What we offer

Elimination of thermal bridges

Elimination of thermal bridges

Profiles for the elimination of thermal bridges make it possible to compensate for heat losses in the most integral places of refrigeration equipment.

Door profiles

Door profiles

Door profiles for cold store doors, a wide range of profiles in different shapes, compatible with many glass pane and door models.

Glass cover profiles

Glass cover profiles

Glass cover profiles are used in refrigeration equipment found in stores, which ensure easy access and perfect presentation.

LED profiles

LED profiles

LED lamp profiles in different shapes and sizes are easy to adjust to different LED bulb models.

Products database

Research and development in the extrusion of plastics

Our research and development team is working on continuous improvement of the extrusion process and injection molding.

They investigate different plastics and look for the set of characteristics with the most flexibility, resistance and precision.

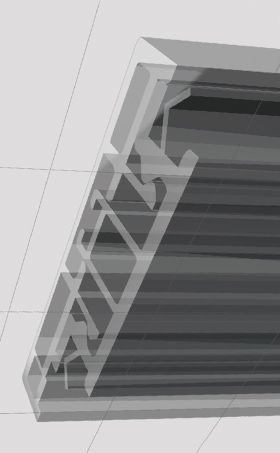

Extrusion is a complex process that makes it possible to use more than one polymer, thus forming a multi-layer structure.

Using two different raw materials results in a more durable and better finished product, so our engineers pursue combinations with better thermal insulation properties to even more effectively eliminate thermal bridges.

The continuous development of manufacturing processes results in technologically advanced profile shapes that fit even better for more effective thermal insulation.

The manufacturing process

Design phase

Heating the plastic

Change of composition

Extrusion

Product cooling

Finished product

Summary of the manufacturing process

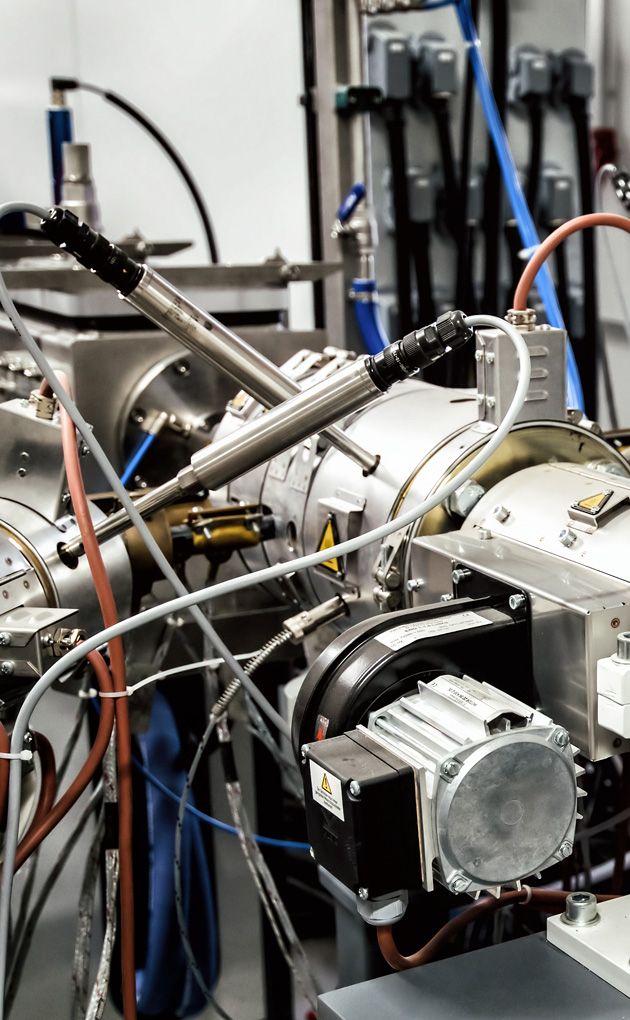

Machine park

Extensive and state-of-the-art machine park

High-precision

Repeatability and precision of produced components.

Continuous process

Quick and automatic production

More durable material

Combination of different polymers

Different lengths

Production of long and complex shapes.

Different profiles

Production of profiles for different applications.

Benefits

Advanced technology using different materials

Precision and aesthetics

Using extrusion technologies guarantees that all components will be produced with due attention to the details.

Extrusion is able to produce profiles up to X m long.

Quick and efficient assembly

The plastic extrusion process is able to produce up to XX components per day.