What we offer

Flush handles

Flush handles

Flush handles for refrigeration equipment are made of durable materials, in different shapes and sizes, and are modern but also highly functional.

Adhesive handles

Adhesive handles

Adhesive handles for refrigeration equipment are available with 3M adhesive tape.

Different colours, shapes and sizes, always easy to install.

Adjustable feet

Adjustable feet

Adjustable feet for refrigeration equipment and food service furniture make it easy to adjust the height and improve the comfort of use.

Drains and funnels

Drains and funnels

A group of components produced by injection moulding, essential for installing food service fittings and building the condensate drain system.

Products database

Please, feel encouraged to choose our injection moulding thermoplastic products.

The production of components with complicated designs and complex shapes makes it possible to adapt to different appliances and products.

Research and development in injection moulding

Our research and development department is continually developing our range of products made of plastics.

The injection methods offer high capacity to produce parts in irregular shapes, so we are continually developing new products for use in the refrigeration and HoReCa industries.

Our engineers investigate the properties of plastics, continually searching for new solutions.

Another task of our engineers is to adjust the material in use in terms of features and needs in the given products.

The manufacturing process

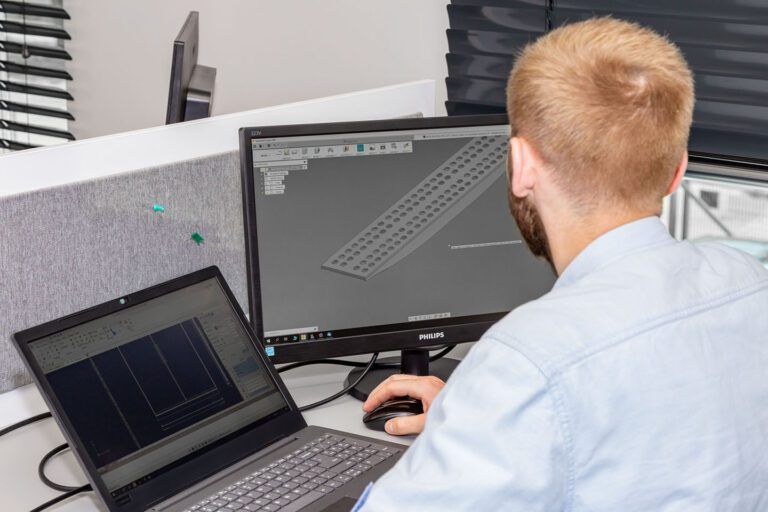

Design phase

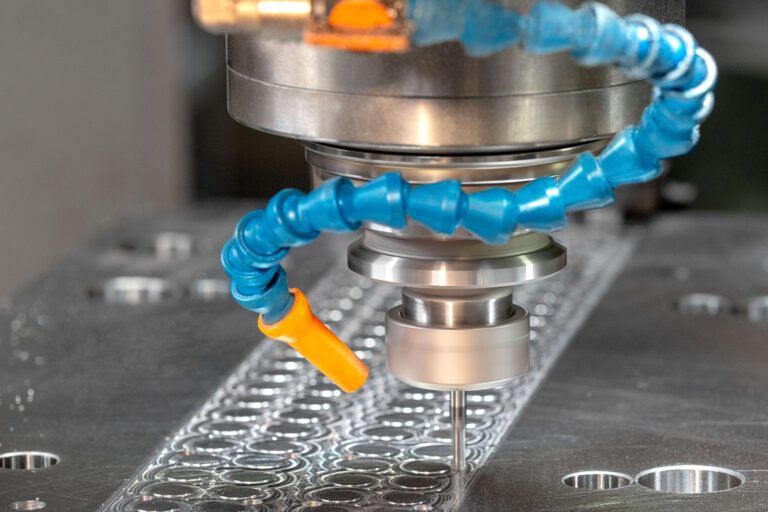

Tool production

Heating and liquefaction

Injection and cooling

Preparation of final product

Summary of the plastic injection moulding

Injection moulding (injection molding) is a plastic forming technology. The process makes it possible to produce components in different shapes. It uses injection moulding machines and CNC machining. It’s cyclical and automated.

Machine park

Extensive machine park

The injection process uses our state-of-the-art injection moulding machines.

Injection moulding machines are designed for the injection moulding of plastics.

It makes it possible to produce many different components in complex and irregular shapes, with many details, such as grooves and recesses.

Variety of shapes

Production of components in complex shapes.

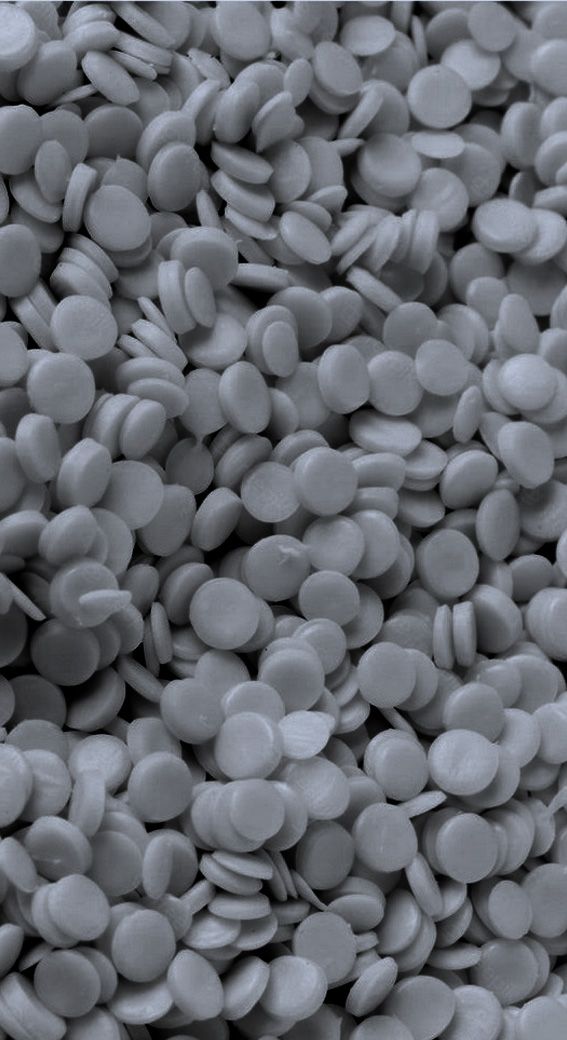

Different materials

Application of pellets of different plastics.

Specificity of details

Production of components with many details.

Full repeatability

Repeatability and precision of the manufacturing process.

Automated production

Automatic production process.

Benefits

High-precision components

Quick and effective production

A finished component is produced as quickly as in several seconds.

The production time depends on the component size and complexity.