Single condensers

Single condensers

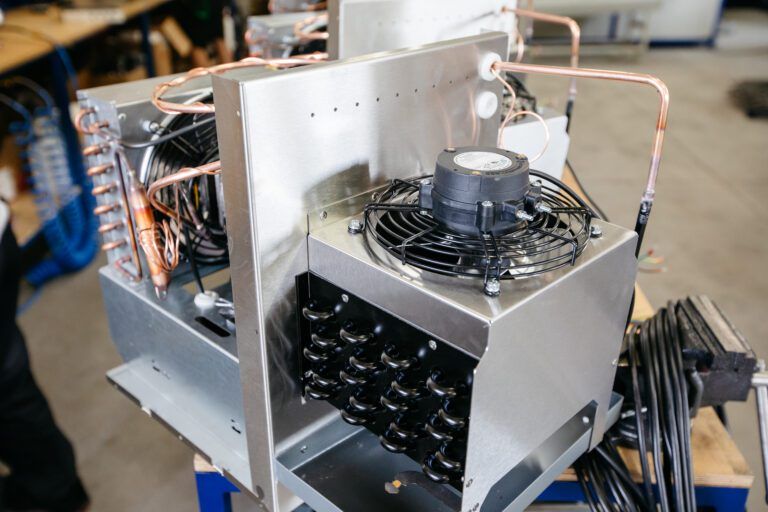

Single condensers designed for small refrigeration equipment are available in versions with different capacities, with different motors, selected by the customer.

Dual condensers

Dual condensers

Dual condensers designed for refrigeration equipment are available in versions with different capacities, with different motors, selected by the customer.

Condenser motors

Condenser motors

Our range includes condenser motors by different manufacturers.

Depending on the customer’s requirements, we offer EC, YZ and EBM motors.

Condenser hardware

Condenser hardware

Essential condenser hardware: suction or discharge fan propeller, fan ring and shroud, also available as single parts.

Products database

Production of condensers – research and development

We are continually developing and upgrading our solutions and product range to provide the customers with supreme support in the implementation of custom designs and the highest quality of the solutions we manufacture.

We are continually expanding our condenser range in line with current trends on the market to address the expectations of many customers. We are constantly improving each of our heat transfer to can develop in air conditioning, cooling systems, heat pumps, etc.

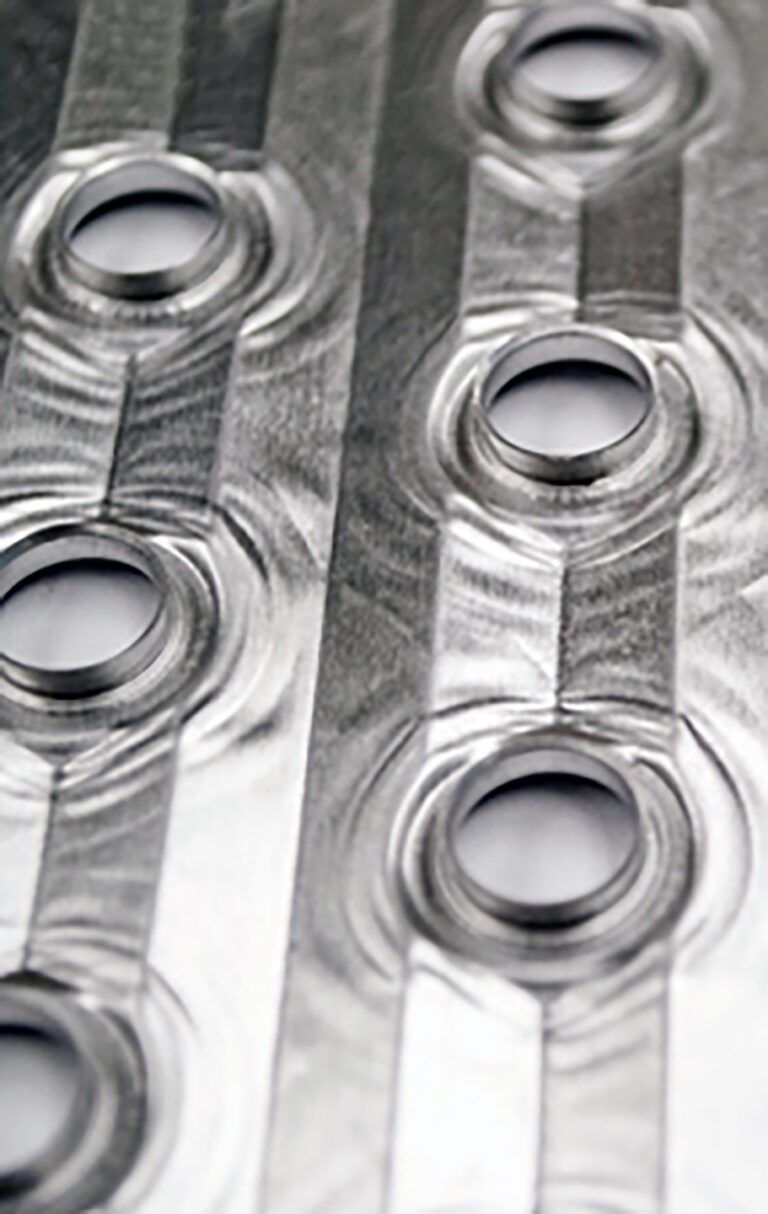

The manufacturing process

Manufacture of exchangers

Component selection

Mounting

Finished product

Summary of the manufacturing process

Application

Place of application of the condensers

We have many years of experience as a manufacturer of condensers.

Our state-of-the-art machine park with high performance process lines is able to manufacture many different condenser models.

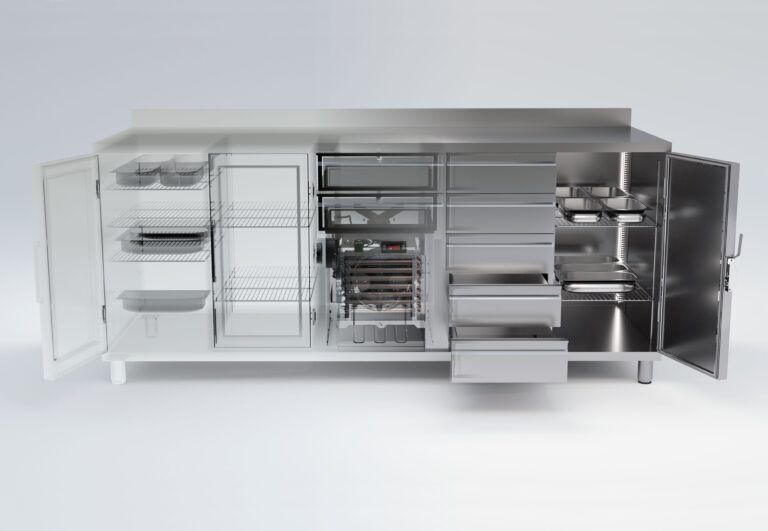

Condensers are used in many places – cooling tables, cooling cabinets, monoblocks and vending machines.

This is why we rely on the production and high availability of this equipment and every customer can find the product they need in own cooling systen.

Different models

Manufacture of different models of single and dual condensers.

Different capacities

Easy selection of the condenser with the right capacity.

Variety of components

Selection of the motor brand and propeller diameter.

Appropriate standards

Manufacture compliant with strict standards.

Reliability

Use of checked and strong materials.

Benefits

Many types

State-of-the-art process line

A well-adapted process line, experience and proven standards support the production of as many as X condensers per day.