Download catalog card of magnetic gaskets and magnetic inserts

Enter your e-mail address, to which you will receive an catalog card of gaskets and magnetic inserts.

What we offer

Magnetic gaskets

Magnetic gaskets

Magnetic gaskets for cold store doors are welded according to the specification provided by the customer, which makes it possible to tightly close the appliance and provides energy savings.

Gasket

PU-090

Gasket

PU-090

A gasket made of soft PVC, welded according to the customer’s specifications, compatible with magnetic insert: PU-M8,9x2,7.

Gasket

PU-033

Gasket

PU-033

A gasket made of soft PVC, welded according to the customer’s specifications, compatible with magnetic insert: PU-M11,6x3,0.

Gasket

PU-088

Gasket

PU-088

A gasket made of soft PVC, welded according to the customer’s specifications, compatible with magnetic insert: PU-M8,9x2,7.

Products database

Research and development in the manufacture of gaskets

Our highly qualified experts of the research and development department continually work to improve the quality and development of our products.

We are proud that as a manufacturer of rubber gaskets and silicone gaskets, we offer only high quality products.

We are continually improving the flexibility and strength of our products, because we want our gaskets to be more resistant to various types of mechanical damage.

Our engineers are also continually developing our range of gaskets by designing new sections that to match new equipment, while making them tighter and much more effective.

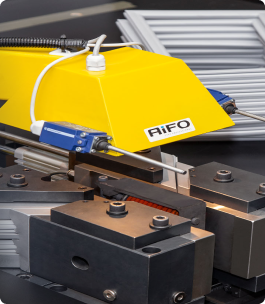

Technology at AiFO

Extrusion

Gasket cutting

Magnetization

Welding

Quality control

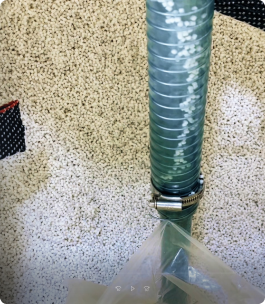

Packing

Summary of the gasket manufacturing process

Machine park

Extensive machine park

Resistance

Production of welded gaskets resistant to low temperatures.

Cross-sections

Production of gaskets in complex shapes.

Custom gaskets

Welding of a gasket according to the customer’s specifications.

Magnetic insert

Use of powerful and strong magnets.

Magnetic insert

Custom selection of the polarity.

Advantages

Reliability

The gaskets are resistant to difficult conditions and very low temperatures.

High power

The magnets used in our gaskets are very effective, since they feature a pull force up to 55g/cm.