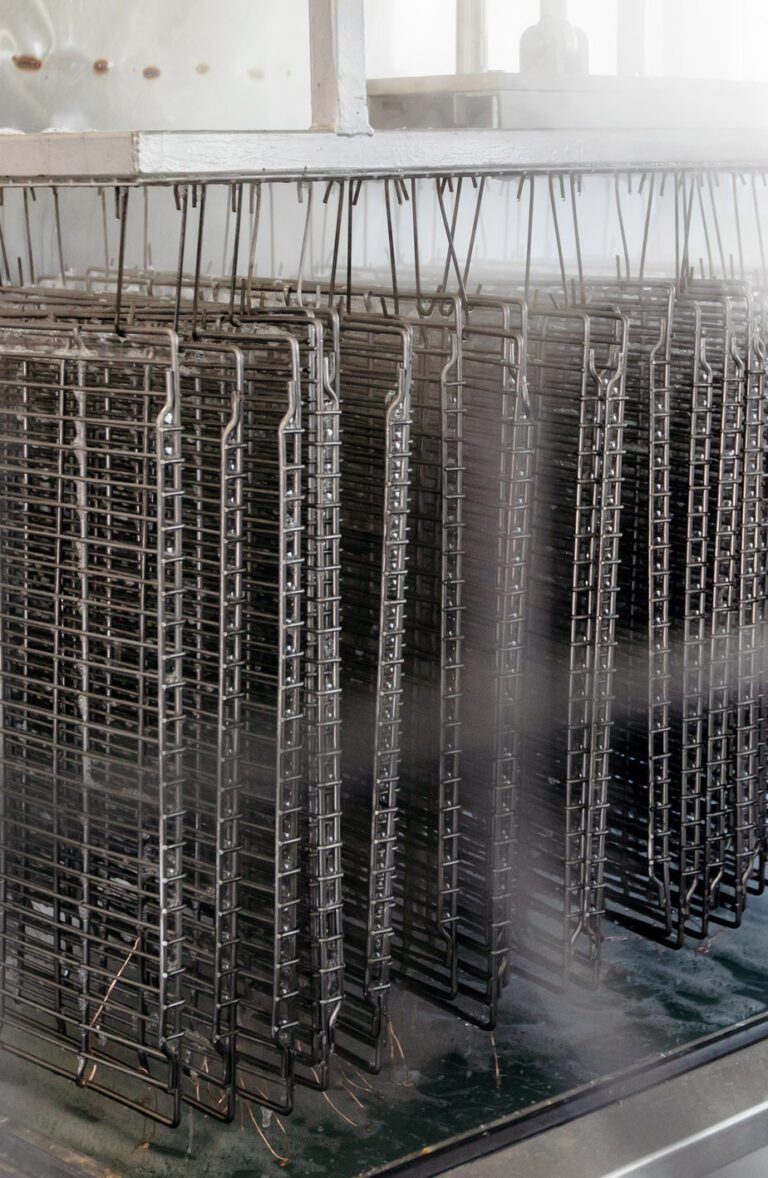

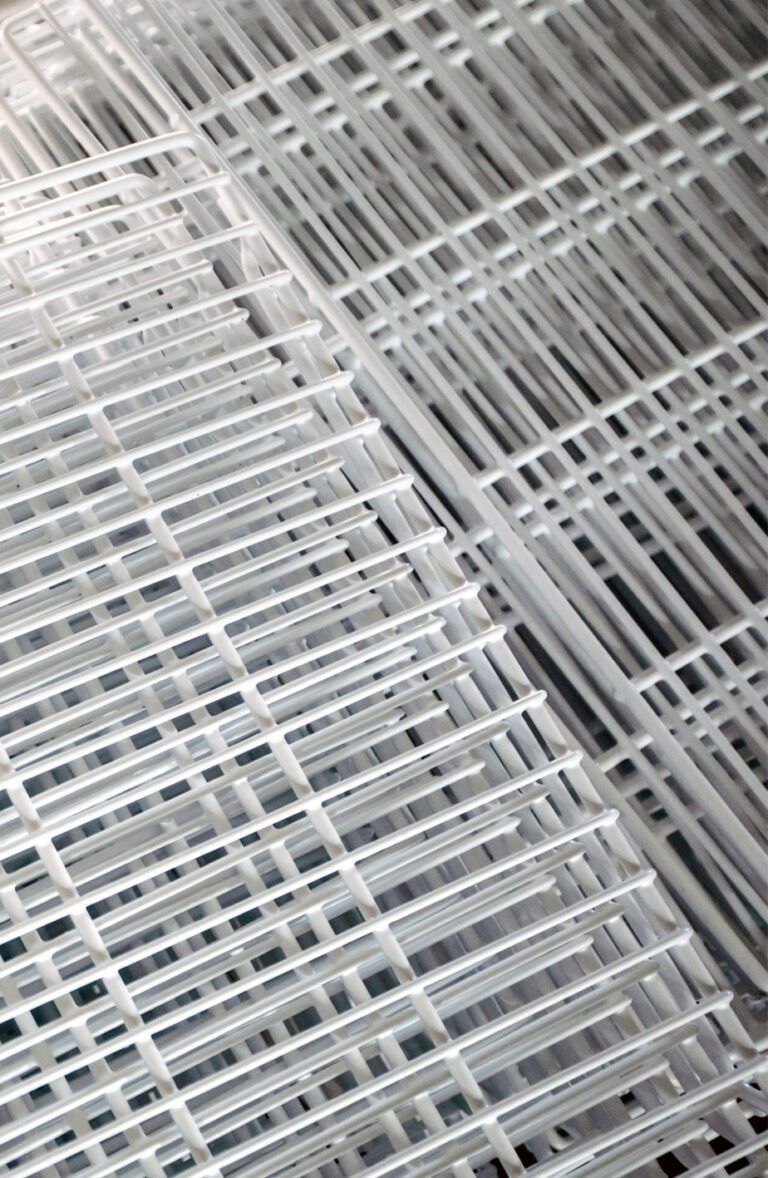

Wire grid shelves

Wire grid shelves

Wire grid shelves provide a free flow of air and perfect presentation of products.

They can be used both in refrigeration and heating equipment.

Wire grid baskets

Wire grid baskets

Wire grid baskets are designed for the easy storage of different types of products. They can be used as equipment in stores, warehouses and other facilities.

Fan shrouds

Fan shrouds

Fan shrouds are an essential component protecting the fan propeller.

We have a wide range of different shroud models with many different diameters.

In-store partitions

In-store partitions

In-store partitions facilitate proper exposure and presentation of products in stores, while making it easy to keep the area clean.

Products database

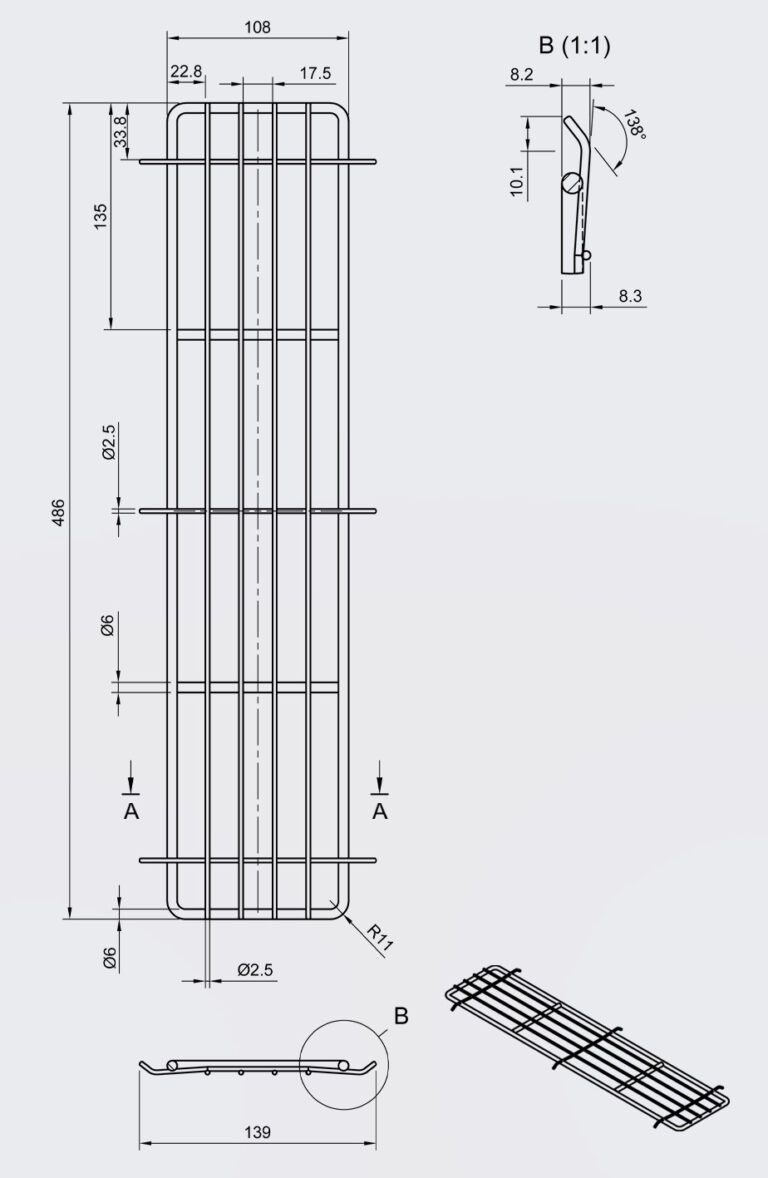

Please feel encouraged to use our CNC wire bending services.

The production of components in complex shapes and custom designs makes it possible for many different customers to use our bending services

Research and development in the wire bending

Our research and development team is continually upgrading every aspect of wire bending. We are always looking for better solutions for bending.

We are upgrading bending tool, bending machine and the manufacturing process to receive only the best quality products.

Our engineers are also looking for new materials and surface protection with better performance.

Only properly selected materials can ensure many years of effective service life.

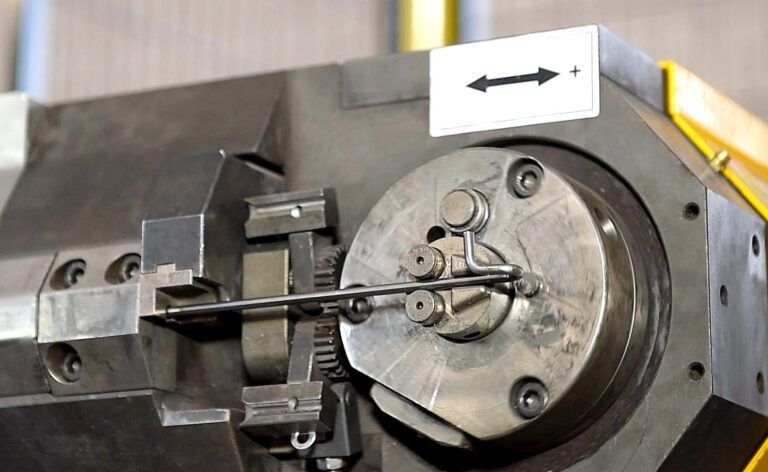

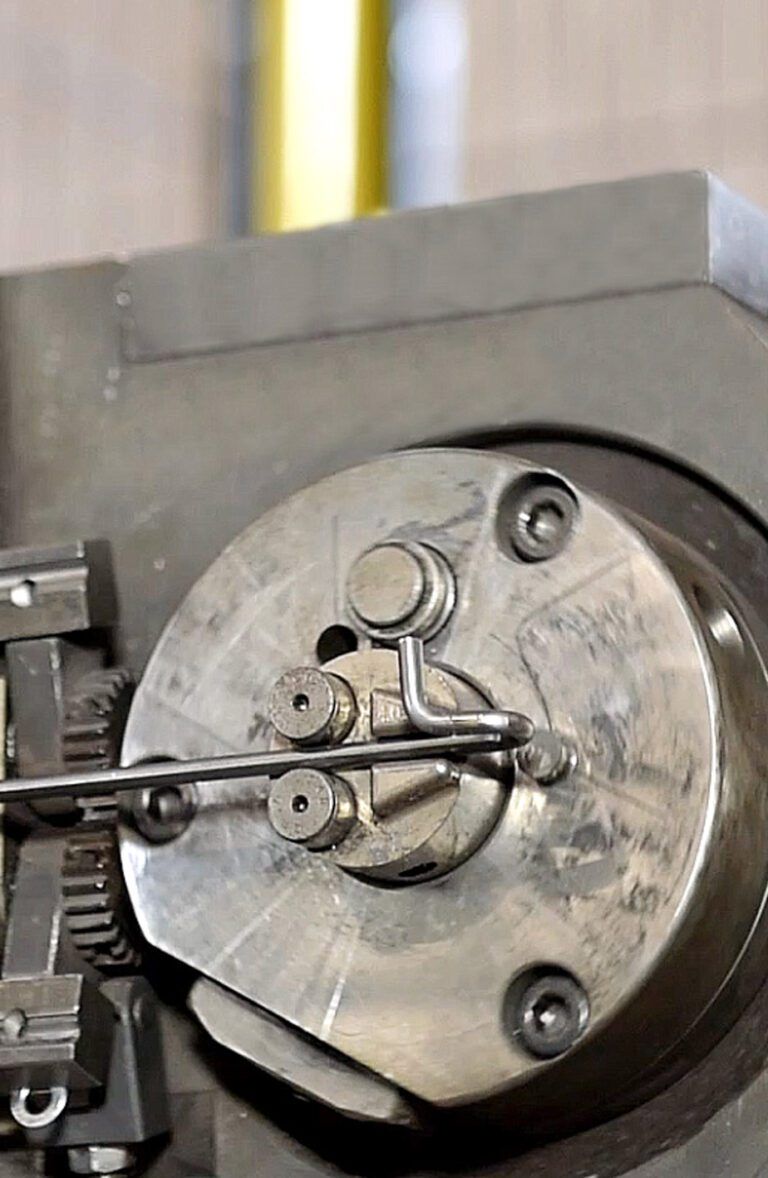

The manufacturing process

CNC wire bending project

Consultation

CNC wire bending

Metal pickling

Fluidisation

Heating up

Finished product

Summary of the wire bending process

Wire bending is a process that consists in feeding wire through a specialised machine.

This is possible with CNC machines, in particular bending machines in this case.

We also bend wires for custom designs to provide our customers with components for use in many different industries.

Machine park

State-of-the-art CNC machines

We have state-of-the-art CNC machines for the quick and comprehensive production of wire components with different diameters.

With controlled CNC machines, all produced components meet high quality standards.

The binding process features high repeatability and high production capacity.

The bending machine makes it possible to produce components in 3D shapes.

This is done easily by bending the wire in three planes.

Moreover, CNC machines are able to straighten wires.

Different bending types

3D and 2D wire bending.

Bending precision

Automatic and high-precision manufacturing process.

Straightening

Wire straightening capability.

Different diameters

Wire bending in different diameters.

Implementation of custom designs

Bending according to the customer’s specifications.

Benefits

Spatial components

3D bending is able to bend wire in multiple planes, which makes it possible to produce components in complex shapes.

Capacity and repeatability

A bending machine makes it possible to repeatably and effectively produce wire components according to the customer’s specifications.