CNC tube bending – process flow

Every tube bending process begins with the design stage. The customer provides a pre-designed project or our engineers prepare it based on the customer’s guidelines. With the ready project, we move to the next stage of the process, namely the preparation of the program for cnc tube bending.

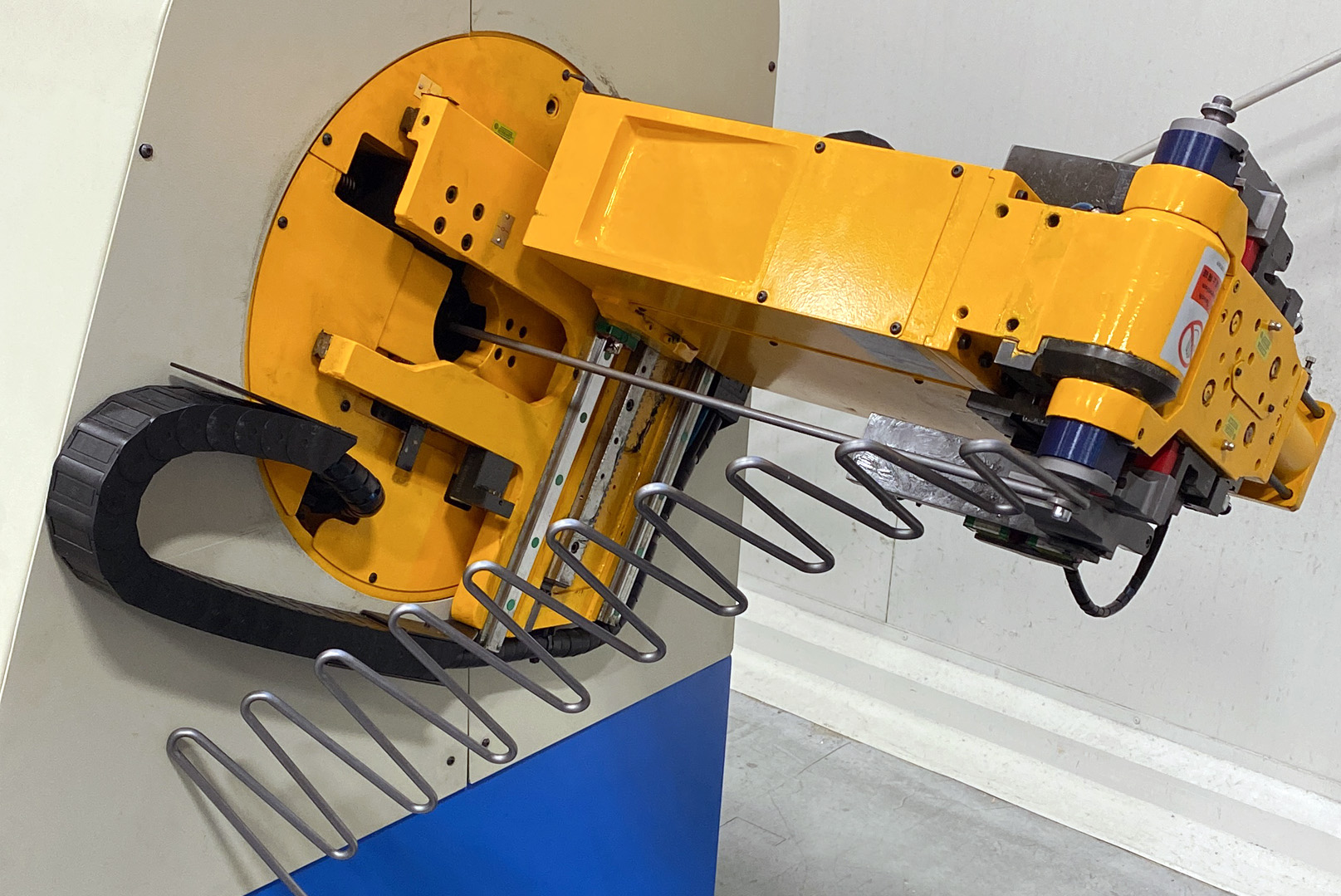

The next stage is 2D and 3D pipe bending, depending on the design and specifications prepared by the customers. A separate phase of the tube forming process is endforming, which is the formation of tube ends that allow them to be joined together. Tube ends can be shaped in many ways. One of them, for example, is the tube flaring.

What materials do we bend tubes from?

We realize bending of steel tubes, copper tubes, aluminum tubes and stainless steel tubes. Especially tube bending in 2D and 3D technology. We have a large production capacity of bends and ends. Bending parameters, such as bending radius, depend on the diameter of the bent tube.

The use of modern CNC tube bending machines, provides repeatability of production and high quality of manufactured elements, ensuring bending at a high level. We encourage you to take advantage of the tube bending services and learn more about our entire offer.

Wide range of products

AiFO Components has thousands of different products in portfolio. Refrigeration components, heating components, various models of gaskets and profiles are just part of AiFO’s offer. We invite you to learn more about the products we offer and all the manufacturing processes we carry out.

Feel free to ask questions about products and solutions, which our qualified technical advisors will be happy to answer.