Silicone heating mats

Heating mats – construction

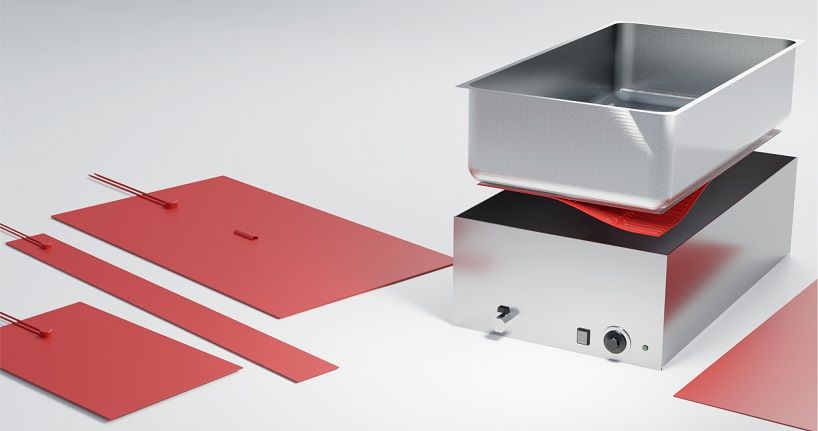

Silicone heating mat is constructed of a heater covered with a high-quality moisture-resistant silicone material. The use of the heating mat – a layer of moisture-resistant silicone – makes it flexible.

One side of the mat is self-adhesive, making it easy to fit the product to the surface of, for example, a bemar container. Sticking the mat ensures perfect adhesion to the surface and very good heat dissipation.

Silicone heating mats are powered by electricity, these products effectively transfer heat to smooth surfaces due to their flexibility.

Silicone heating mat – voltage

The standard voltage of 230 v is used for these types of products. This makes silicone heating mats easy to install anywhere.

Silicone heating mat – installation

Installation of the heating mat is easy to apply. Heating mats can be made with glue, which facilitates the installation of the mat to the bain-marie. Standard sizes of the bain-marie chamber are, for example GN 2/1, GN 1/1, GN 1/2, etc., for which appropriate heating mats should be selected. It’s also possible to make silicone heating mats to custom dimensions.

Heating mat can be fitted to the bemar container, no matter what shape it has. Even rounded sides of bemars are not an obstacle to installation. This is due to the high product flexibility of silicone heating mats.

Silicone mats – where they are used

Silicone heating mat is mainly used in catering serving lines. The use of such heating elements allows the products stored inside the bain-maries to be kept warm all the time. This is what the heating mats are responsible for, the task of which is to constantly heat up and maintain a certain temperature. Depending on the model, the mats have different heating power. Maximum working temperature is closely related to the materials used in production of the mat.

Models without a thermostat and with a thermostat are available. The built-in thermostat allows you to easily control the temperature, without the need to install measuring systems. Depending on the heated food and requirements, you can choose heating mats with the appropriate power.

Heating mats are also used as heaters for other devices. They can be used, for example, as a barrel heater. The self-adhesive surface of the mat allows its application to be applied to other products with smooth surfaces and heat conduction will still be at a high level.

Silicone mat – version with a drain hole

Heating mat with a drain hole gives the possibility of increasing the heating surface for more demanding customers. Silicone was also used in its production. This is a guarantee that the heaters are well insulated. As a result, the temperature is higher and the whole heating mat works very effectively.

Heating mats – underfloor heating

Heating mats are also used in construction. They differ in size, construction and material. Heating mats are often used as underfloor heating (similar use is found in heating cables). Such a mat is made of fiberglass, for example, and the cable itself has insulation made of PVC with high temperature resistance.

Such items as the control unit for underfloor heating system and the panel for underfloor heating controller are used as additional equipment. They allow you to easily monitor and control the temperature. Measuring and easily changing the temperature and adjusting it to the prevailing conditions is a great convenience, so it is worth installing a floor sensor.

Pros of underfloor heating

Big advantage of underfloor heating is its efficiency, which allows you to use this solution as an independent and basic heating, without the need for additional heating in the rooms. Underfloor heating can be compatible with any type of floor. There are even special heating mats for floor panels and tiles.

Easy regulation and adjustment of temperature with a floor sensor allows you to program a temporary heating program. It translates into comfort and satisfaction of users and optimization of operating costs.

Properly insulate the floor

Insulation is an important element in the operation of underfloor heating. Adequate insulation should be provided so that the heat does not leak from the room, e.g. into the ground. Lack of insulation or a poorly insulated floor results in heat losses. At the same time it will translate into increased operating costs. In turn, good insulation translates into easier maintenance of the optimal temperature in the bathroom and any other room where underfloor heating is installed.

Contact with advisors

Heating mats we offer are manufactured from the highest quality materials. Our highly qualified staff of experts will be happy to answer all your questions.

Ordering products at AiFO is a guarantee of purchasing high-quality products, availability from stock, efficient and fast shipping. Wide range of heating elements and a competitive price make us an attractive supplier.