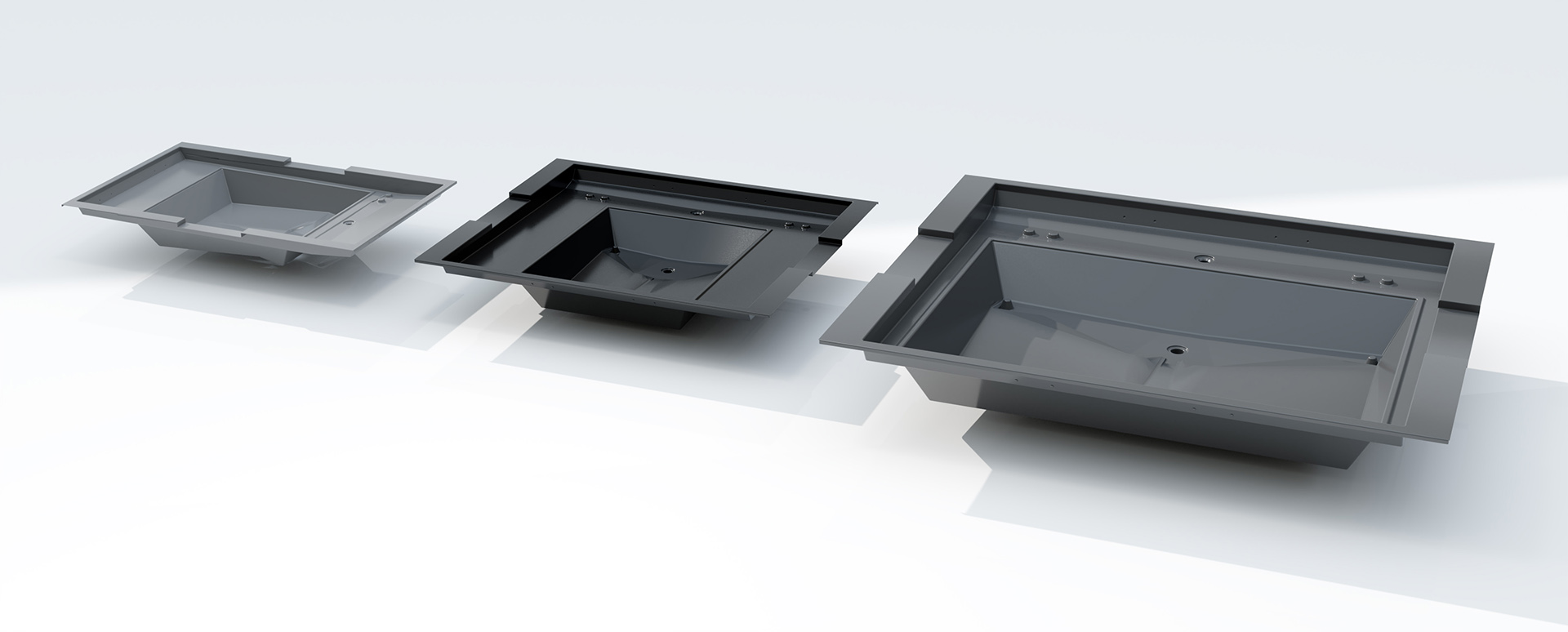

Thermoformed components

The method of thermoforming plastics offers the possibility of producing parts with complex shapes from thermoplastics. This method – along with injection molding technology – is often used in many industries.

Thermoforming of plastics

Production of thermoformed parts involves the use of specialized machines designed for vacuum thermoforming. In the thermoforming machine, a sheet of material made of plastic (e.g. HIPS, ABS) is heated, the high temperatures plasticize the material, which then goes to the mold and, as a result of vacuum, obtains the shape of the mold. This stage is made possible by exceeding the plasticity state of the material. After obtaining the shape, the whole thing is cooled down. Then the element is separated from the mold – this process is automatic. The last stage of production is cutting the product and cutting off the excess material to obtain the final product.

Vacuum forming – additional processes

Thermoformed element can undergo additional processes. It can be painted in any color. Holes can also be made in it or additional structural elements can be installed, e.g. to increase stiffness.

What do we produce by vacuum thermoforming?

Application in packaging production

Thermoforming of plastics makes it possible to produce items that are used in many different industries. Transportation dividers, packaging and containers for catering, packaging for pharmaceutical products are produced in this way. Depending on the industry and purpose, different material is used, which has different properties and parameters.

Automotive applications

Thermoforming of plastics is particularly well suited to the automotive industry. This type of manufacturing allows for production of such elements as: wheel arches, covers, fairings, bumpers.

Vacuum thermoforming of large components

Thermoforming is also used to produce large-size elements. Such application facilitates the production of many products used, for example, in refrigeration equipment.

Thermoformed components have many advantages. One of the biggest advantages is that they are made entirely from a single sheet of plastic obtaining a complicated shape. Such a shaped element provides specialized tooling.

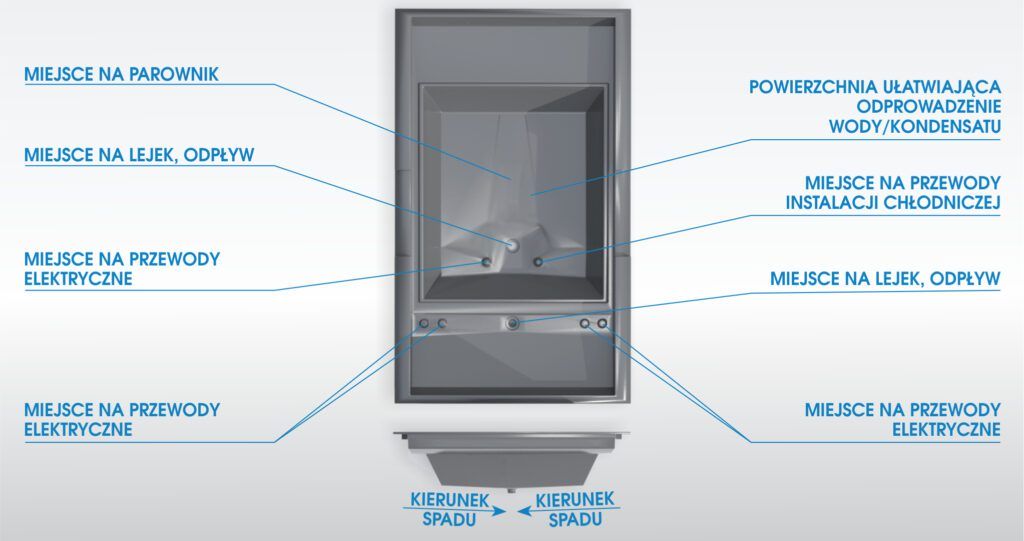

The shape of the temoformed element used in refrigeration equipment, for example, the body container, is strictly tailored to the design and the tasks to be performed, so it has:

- appropriate slopes that facilitate the drainage of condensate,

- shaped place for the evaporator,

- holes for the drain funnel and electrical wires.

Thermoformed components – provider of modern solutions

The use of thermoforming technology allows the production of many different elements from thermoplastic materials. Technology facilitates the production of large components with numerous indentations, grooves and channels. Thermoforming is a technology that enables the production of elements in short production series at a relatively low cost of production implementation and high quality. In summary, the design and production of elements made of thermoplastic materials has many applications in many industries. Products are being used as inserts, spacers in the packaging industry, in the automotive industry as wheel arches, covers, bumpers and in the refrigeration industry as body elements, cover elements, doors, side panels, e.t.c.