Evaporator defrosting – methods

Evaporator defrosting process can be implemented in several ways. Depending on the conditions in which the equipment operates, its specifications, climate and temperature – different solutions are used for the equipment.

Evaporator defrosting by compressor stoppage

Evaporator defrosting is done automatically, through a programmed shutdown of the compressor, and the running fan speeds up the defrosting process. After a time specified by the controller, it restarts and the compressor runs normally. This is one of the simplest methods to defrost the heat exchanger. This is a good solution for refrigeration units operating at positive temperatures and evaporation temperatures of just below zero degrees Celsius.

Defrosting time is programmed and everything is done automatically. The cost of defrosting for this solution is minimal, as no additional components are needed for it.

Disconnecting the device from the power supply

In refrigeration units where the defrosting process cannot be carried out while the unit is running, this is the method used. At the beginning, the device should be emptied of the products inside. Then the whole thing should be disconnected from the power supply. After defrosting the ice inside, remember to drain the water.

Defrosting time varies and depends on the amount of ice build-up. Emptying the unit of the products inside also absorbs the time of the maintenance staff. The cost of defrosting is closely related to the time spent on these tasks.

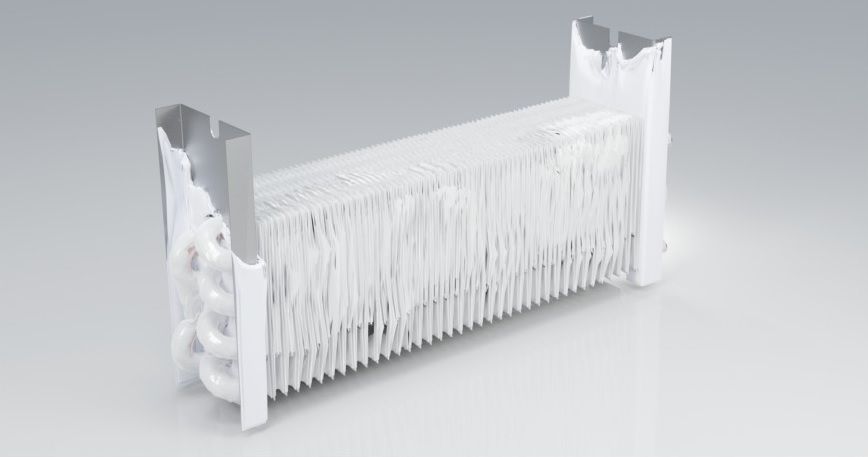

Defrosting by electric heaters

Electric defrosting is possible through the use of electric heaters. Defrosting is done automatically. This solution is relatively easy and cheap to implement. This is because electric heaters are fairly low cost components to purchase.

However, it is not ideal for all types of refrigeration equipment, as electrical components can cause a fire risk. Electric heaters also consume a significant amount of electricity and increase the temperature in the refrigeration compartment.

Defrosting with hot gas

Hot gas defrost uses the heat of hot refrigerant vapors. It’s supplied through a hot vapor pipeline, directly from the compressor discharge line to the heat exchanger. During the defrosting process, the cooler is converted into a condenser, and the supplied heat causes the defrosting process.

This solution is possible, thanks to components such as the compressor, evaporator, condenser, expansion valve and solenoid shut-off valve.

The defrosting time is shorter, as with other methods. The cost of heat when defrosting with hot gases is low. It can be up to three times lower than when using electric heaters. In this method, however, it’s expensive to install the defrosting system.

Hot steam defrosting with four-way reversing valve

This type of evaporator defrost uses the process of reversing the refrigeration circuit for the defrost time. Hot high-pressure refrigerant vapors extruded by the compressor, through the use of a four-way reversing valve, can be directed either to the condenser or through the suction line to the evaporator, where it melts the ice.

Defrosting time is short, the process doesn’t consume much energy and there is no fire risk. The temperature rise in the refrigeration chamber is also minimal. The disadvantages of this solution are the high cost of implementation and its technical difficulty.

Why is the defrosting process so important?

Proper and regular defrosting of the evaporator helps prevent the formation of large layers of ice on the surface of the evaporator and protects against a drop in performance. The refrigeration unit will properly cool the products inside, even at higher ambient temperatures.

It’s therefore worthwhile to establish a defrost cycle that will ensure optimal operation of all our refrigeration equipment. The factors that affect the frequency of defrosting and that should be taken into account are temperature and humidity.

At lower temperatures, the heat exchanger must be defrosted periodically. The lack of regularity in the defrosting process and a poorly chosen solution can lead to evaporator icing. Removing a thick layer of ice from the exchanger will be much more difficult, and the defrosting process itself will take much longer. It should be remembered that the lower operating temperature of the unit, the more often the defrosting takes place, which is why a properly planned and executed defrosting cycle is so important.

Where else is the defrosting process used?

Defrosting process is realized not only in refrigeration and low-temperature equipment. It’s also necessary in heat pumps, air conditioners, refrigeration chambers.

Necessary equipment used for evaporator defrosting

Already knowing the methods of defrosting heat exchangers, we can choose the right one and select the necessary components.

Certainly, heater and electric defrosting are among the most widely used solutions. The low cost of installation, the low level of complexity and the high availability of components translate into high interest in this method of defrosting.

With the continuous development of technology, we are constantly looking for new solutions to make refrigeration equipment:

- operate more efficiently,

- have less heat loss,

- defrost the evaporator surface more effectively.

We are developing methods, such as hot vapor defrosting. It allow the evaporator to be defrosted efficiently. The heat generated does not significantly increase the temperature inside the refrigeration chamber. Also, in the case of electric heaters, the products are being developed to make them safer, more durable and use less energy.

Contact with advisors

We encourage you to contact our experts, who will help you select the right components for effective evaporator defrosting. Electric heaters of sufficient power for effective defrosting, condensate drainage system and all other necessary components.