What we offer

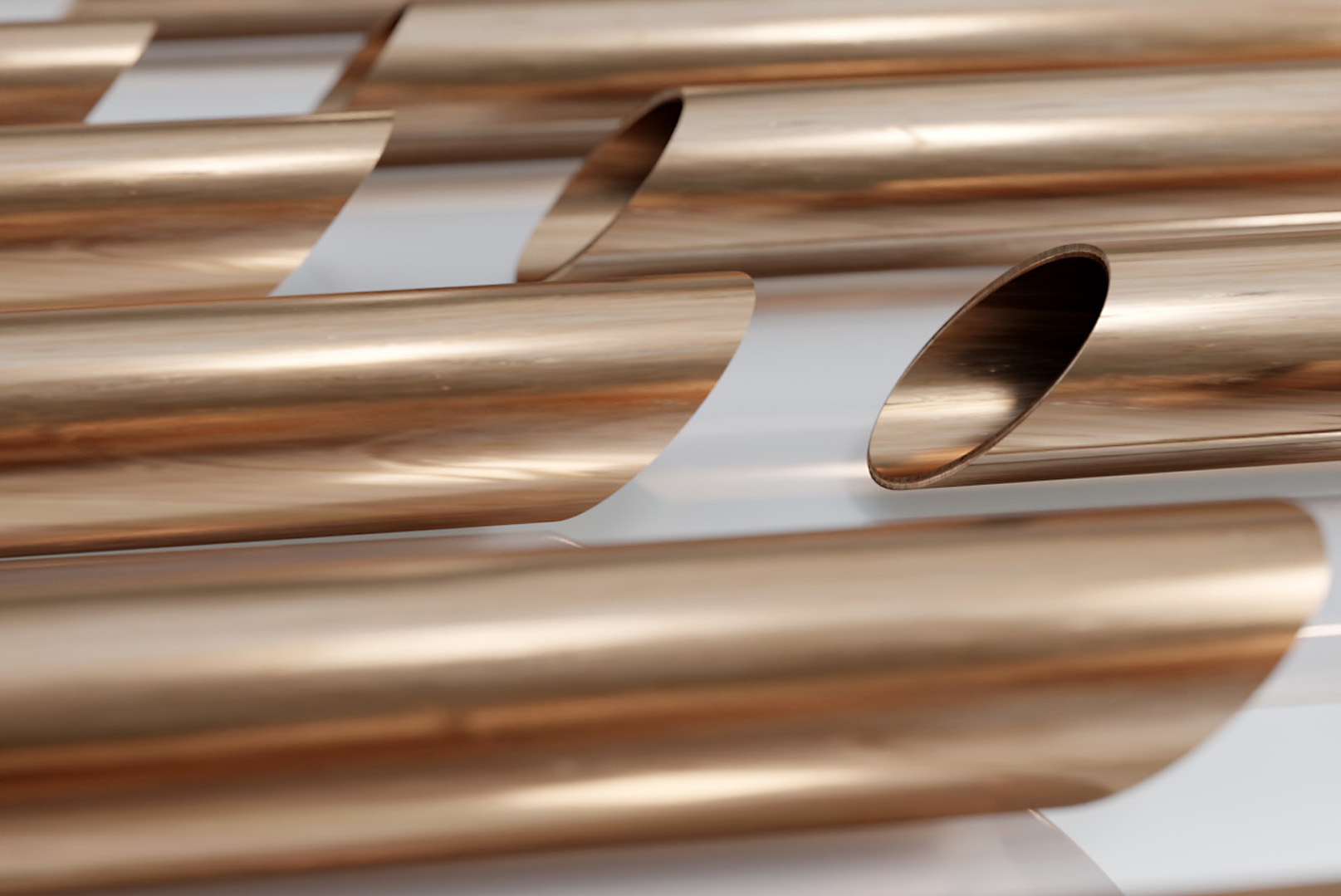

Copper tubing machining and bending – research and development

Our research and development department is continually monitoring technical innovations in the refrigeration industry and developing its qualifications to provide the customers with supreme support in the implementation of custom designs and the highest quality of the solutions we manufacture.

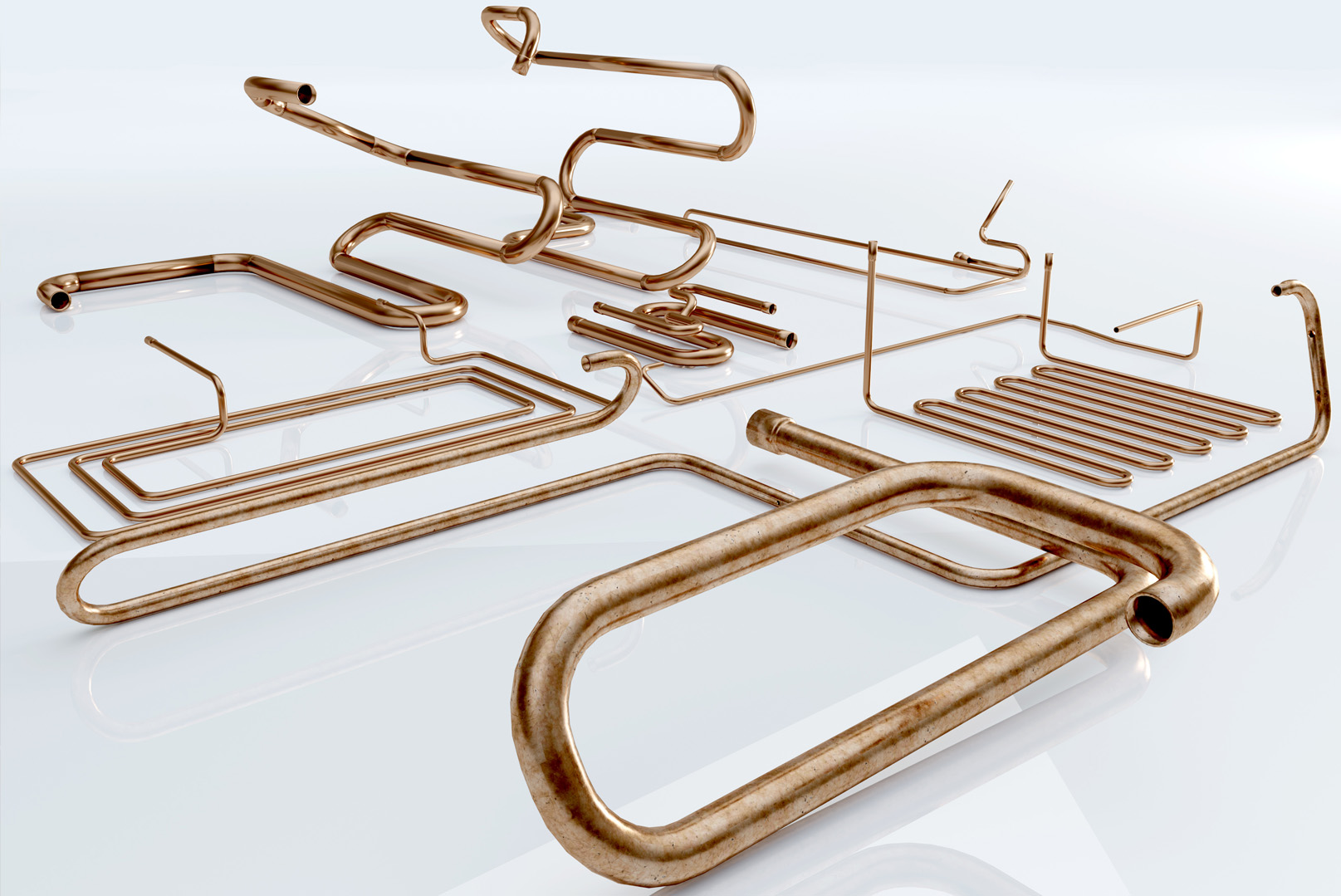

We are continually expanding our product range in line with current trends on the market to address the expectations of many customers. Copper pipe, refrigeration copper fittings – these are some of copper components.

The manufacturing process

Design phase

Cutting

2D bending

3D bending

End Forming

Summary of the manufacturing process

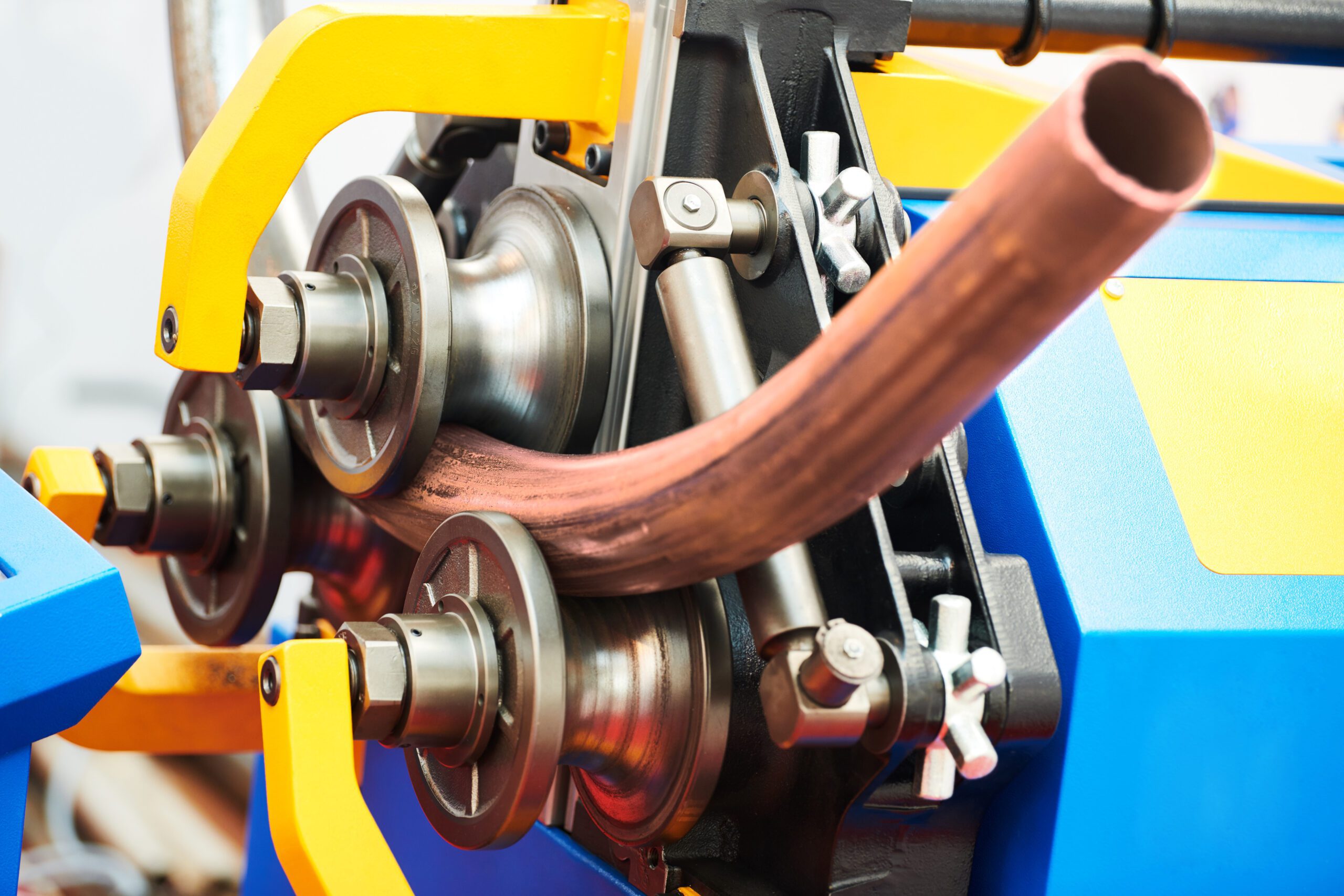

Copper tubing machining and bending is a process in which a specialised machine deforms a copper tube.

The final stage of endforming is also performed on automated CNC machines.

Machine park

State-of-the-art equipment

Copper tubing machining and bending is a process in which a specialised machine deforms a copper tube. Pipe bending 2D and 3D, processing – that are some of process.

The final stage of endforming is also performed on automated CNC machines.

Implementation of designs

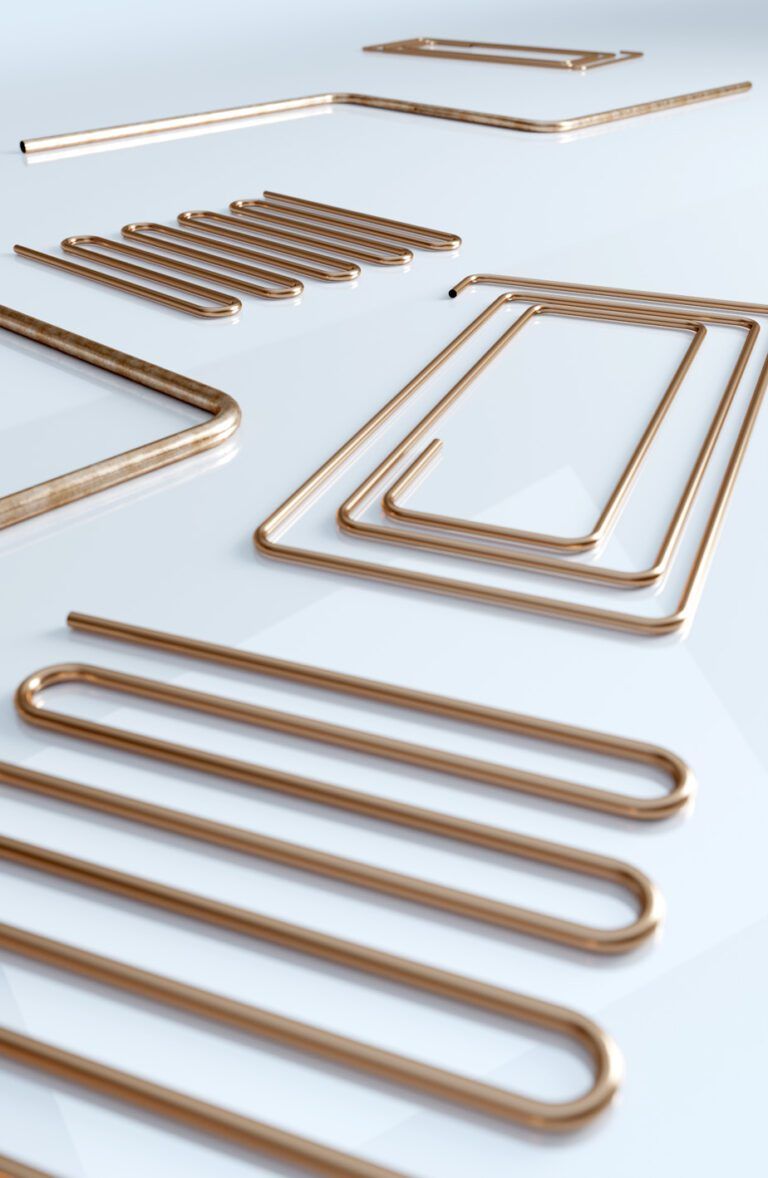

Copper tubing bending in accordance with specifications.

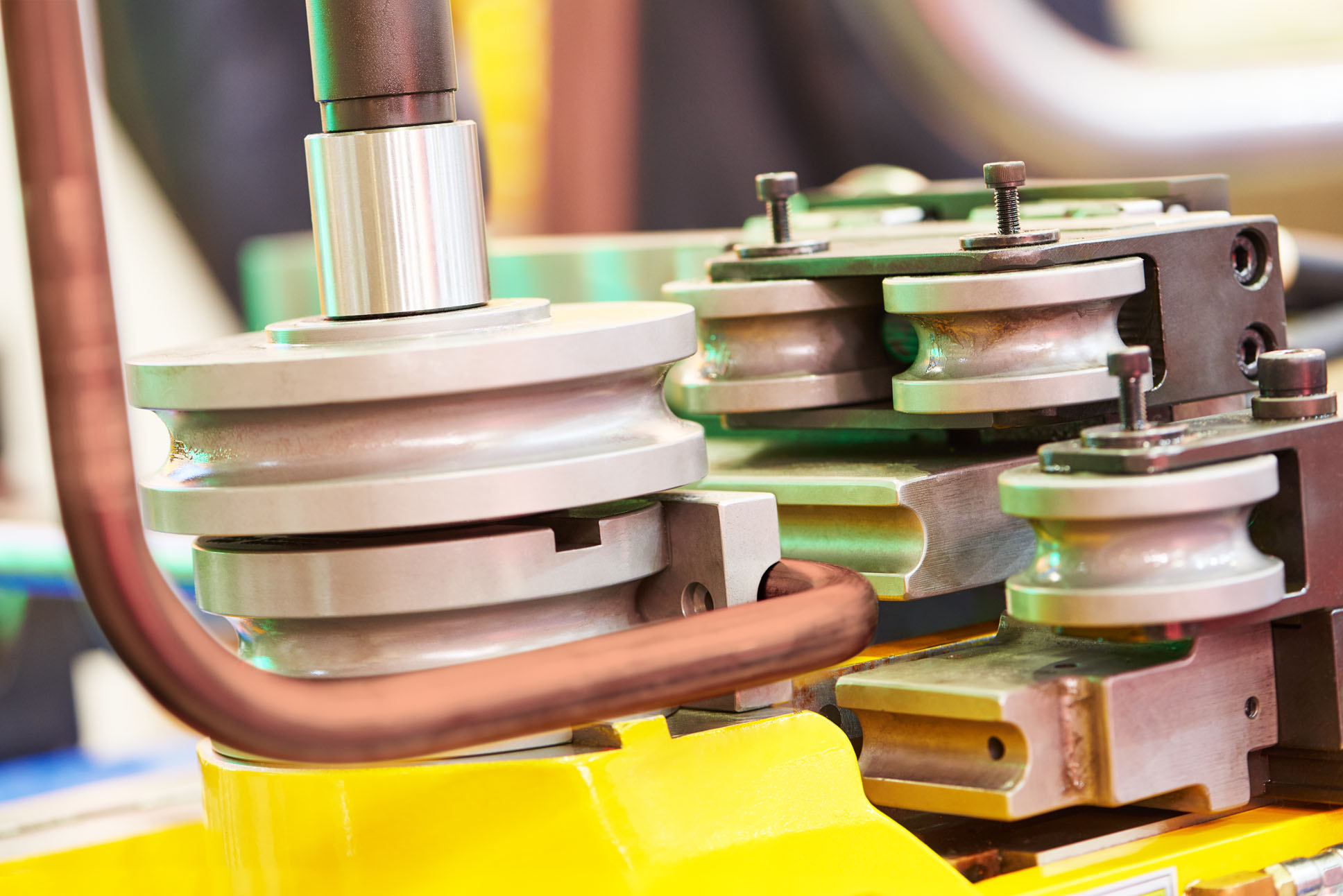

2D bending

2D copper tubing bending.

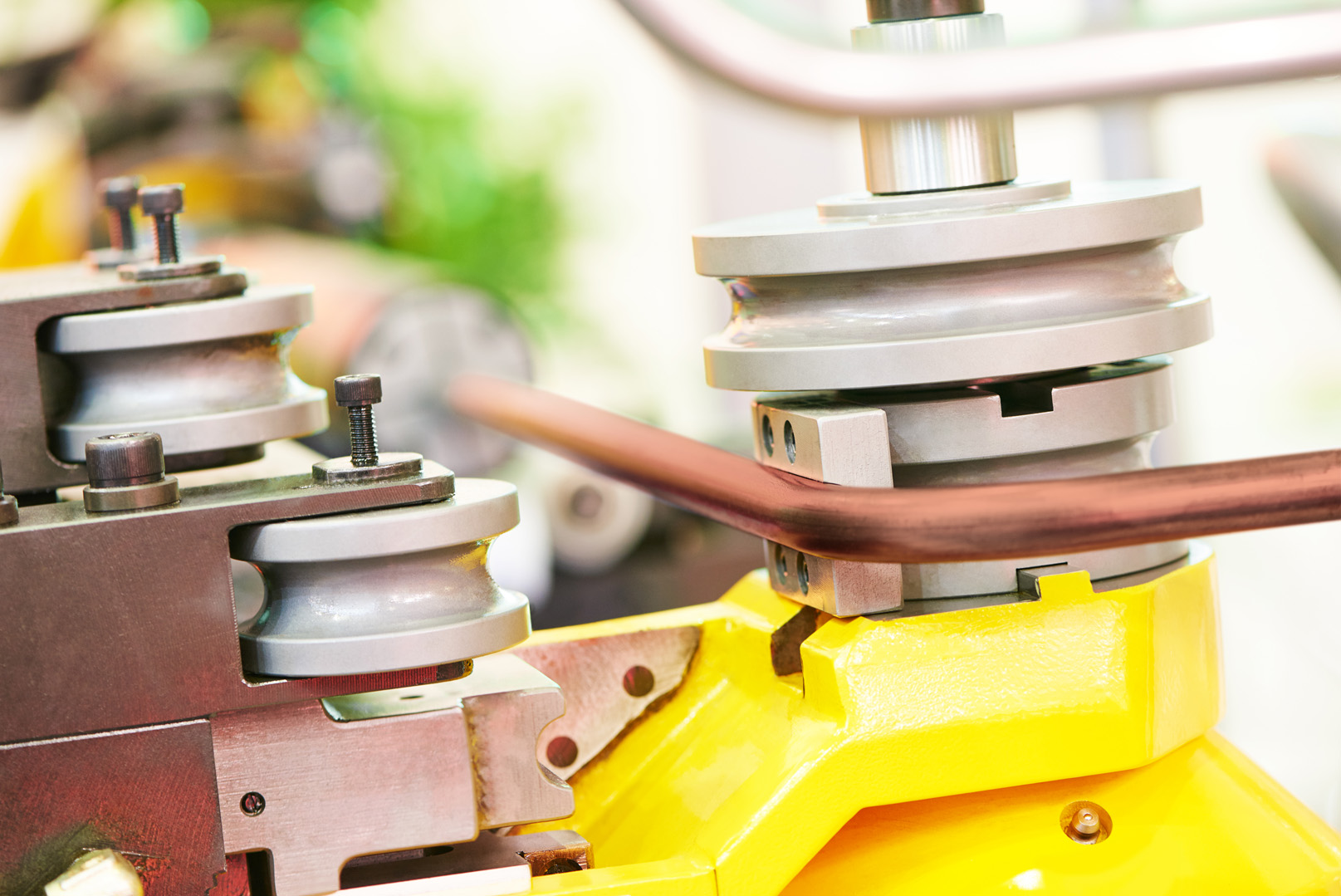

Spatial bending

3D copper tubing bending.

Precision

Repeatability and precision of the produced components.

Endforming

Expanding copper tubing – can be combined in series.

Advantages

Time savings

With our experience and know-how, we will implement even complex designs.

We support our customers at every stage of the design of copper components, saving their time and resources.

From 1 piece to serial production

The copper tubing bending machine provides repeatable and effective production of copper components according to the customer’s specifications.

According to specifications

The endforming, or finishing copper tubing, is performed according to the customer’s specifications.