What we offer

Table monoblock chiller

Table monoblock chiller

The table monoblock chiller is a complete refrigeration assembly that is quick and easy to install, and ready for use immediately after installation.

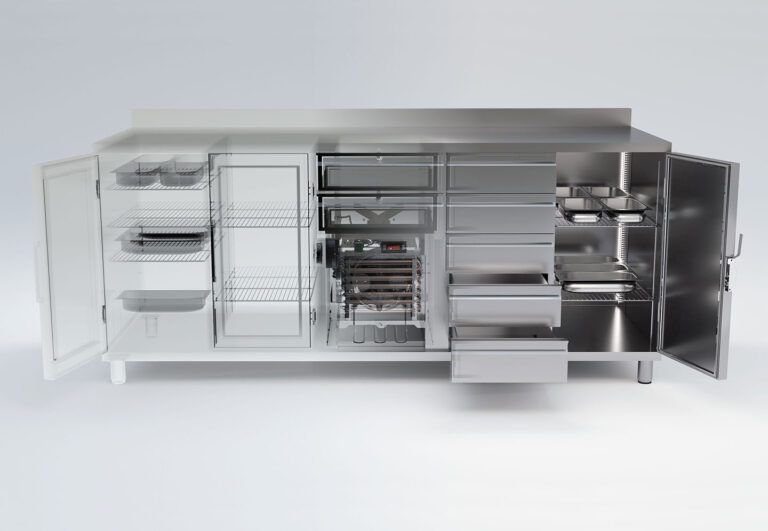

Cabinet monoblock chiller

Cabinet monoblock chiller

The cabinet monoblock chiller is a complete refrigeration system and Plug&Play appliance that is ready to work immediately after plugging in.

Chamber monoblock chiller

Chamber monoblock chiller

The chamber monoblock chiller is a complete refrigeration system that is ready to serve its purpose immediately after installation in the refrigeration appliance.

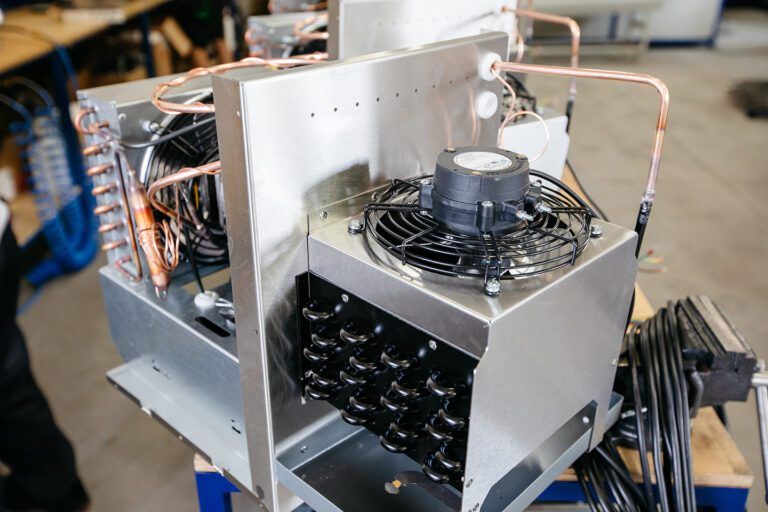

Condenser units

Condenser units

Condenser units for refrigeration equipment feature the essential components, such as the condenser and the compressor, available in many different versions.

Products database

Research and development in the manufacture of monoblock chillers

Our research and development department is continually working to improve the efficiency of equipment, such as the monoblock chiller.

As the performance and parameters are improved, monoblock chillers become more efficient, more resistant to difficult conditions and ready for a longer service life.

The sum of these activities translates to the quality of the produced components and parts, which in turn makes the entire monoblock chiller a better and more complete product.

The manufacturing process

Mounting

Finished product

Easy replacement

Summary of the manufacturing process

Applications

Where are monoblocks used

Monoblock chillers manufactured in our state-of-the-art machine park have many applications.

With our special process line, we adhere to standards and regulations in production.

We only use proven and tested components to provide you with high quality products according to your specifications.

With high manufacturing standards, compliance with standards, as well as universality and ease of replacement, monoblock chillers are eagerly selected and used in different refrigeration equipment. Various types of monoblocks are used in refrigeration, heat pumps, pharmaceutical industry. Ther’re integral part of cold rooms, refrigerated counter, refrigerated cabinet, etc.

Different models

Manufacture of monoblock chillers with different capacities and sizes.

Easy replacement

Easy replacement in case of failure – replacement of the entire monoblock chiller.

Plug & Play

Appliance ready for installation.

Monoblock appliance

All the required components in a single enclosure.

Quick installation

Quick and convenient installation of the monoblock chiller in refrigeration equipment.

Advantages

Natural refrigerant

In monoblock chillers, natural R290 propane gas is used.

This refrigerant is compliant with all new EU Directives and manufacturing standards.

Plug & Play

Complete and closed solution

A cooling unit with all the required components in a single, compact enclosure is a monoblock chiller.