Are your electricity bills already too high? Are you worried they might increase even more in the future? Do your refrigeration devices consume a lot of electricity? This could be related to energy losses occurring at the junction of the refrigeration doors and the body of the device, specifically talking about the gasket.

Welded Gaskets Made of Soft PVC

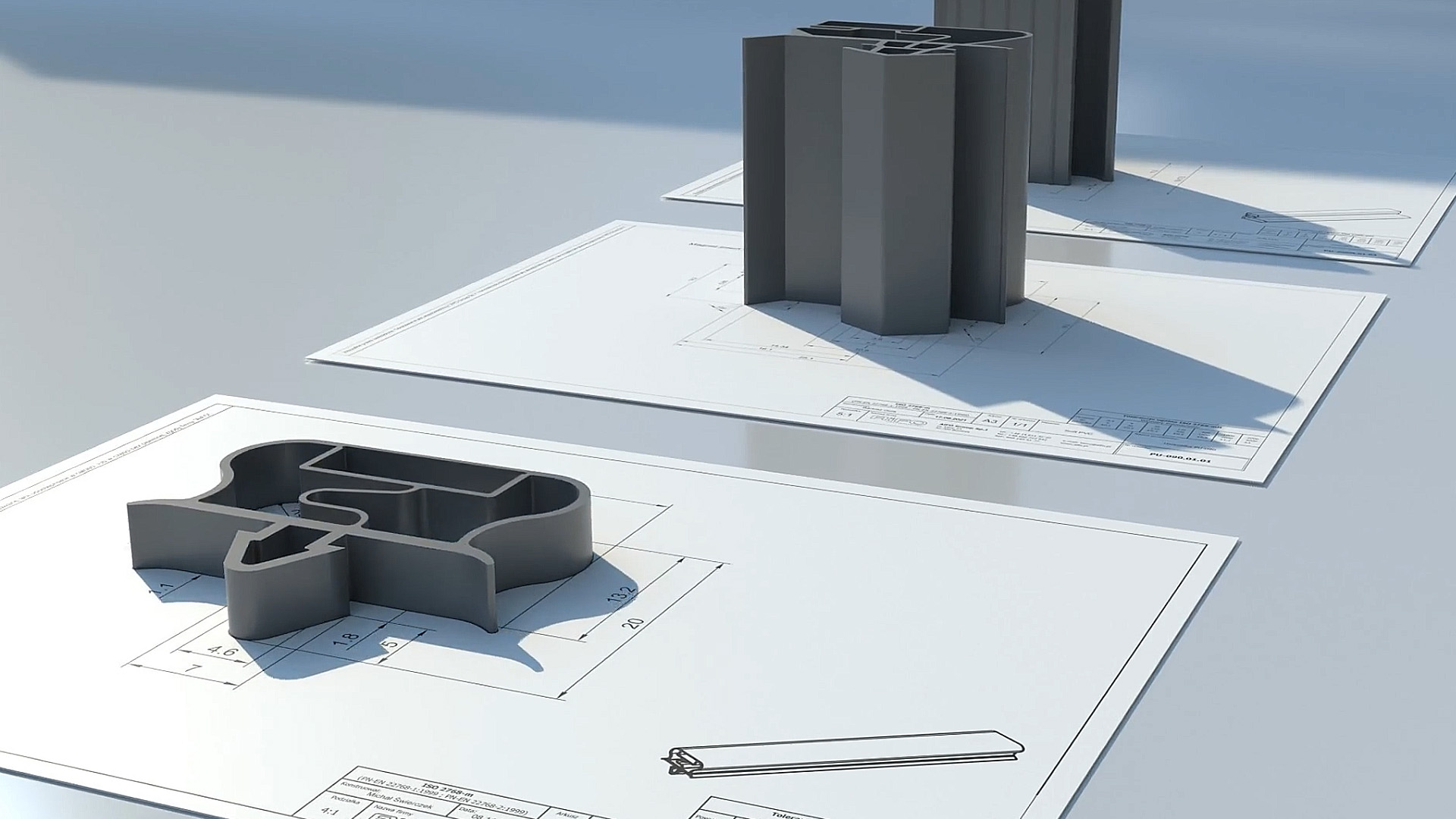

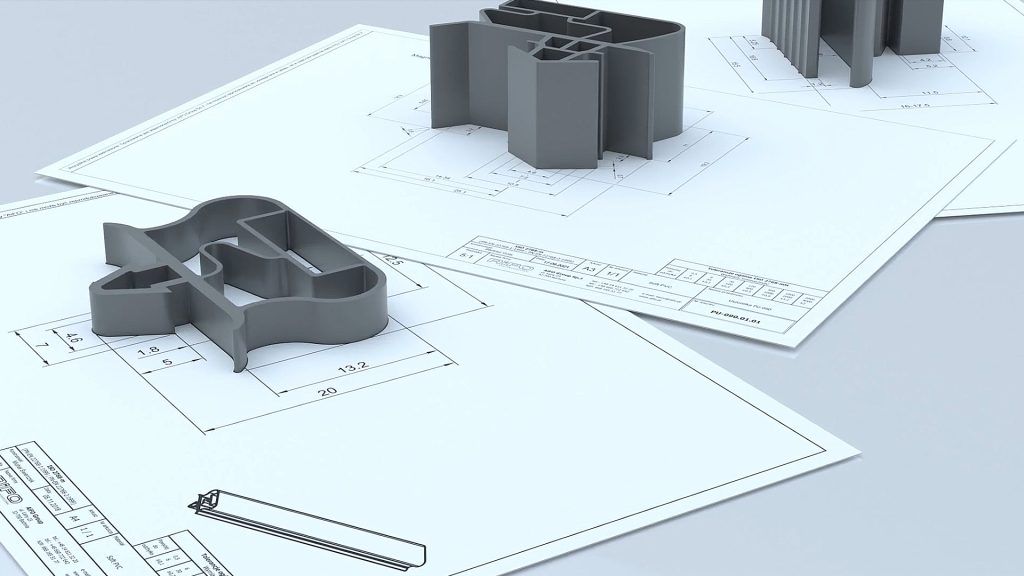

Key aspects in the production of magnetic gaskets are the material and the quality of the seal’s craftsmanship. Gaskets produced at AiFO Components are made through the extrusion process of soft PVC plastics. In addition to PVC (polyvinyl chloride), TPE (thermoplastic polyester elastomer) is also used in the production of gaskets. Our range includes multi-chamber gaskets, which depending on the mounting method, are pressed, glued, or screwed to the profile. Particularly, the first solution is highly regarded for its convenience and speed of installation.

But what are gaskets? A gasket is a simple element – a type of sealing – with a specific shape and dimensions. Gaskets used in refrigeration, specifically in refrigeration furniture, are made, among others, from soft PVC. The gasket is placed in the refrigeration door profile, at the junction with the body of the refrigeration furniture, and allows for achieving the appropriate tightness.

The variety of gasket models produced at AiFO Components makes it easy to choose the right model for a specific profile. Gaskets work well in contact with various materials.

Thermal Conductivity of the Material

The heat conduction coefficient λ (lambda) is the amount of thermal energy flowing through a certain mass of the sample, due to an external temperature difference. It is one of the most important characteristics of insulating materials. The lower the value of λ (lambda), the less the material conducts heat, and therefore, the better it insulates against heat loss. Values of the heat conduction coefficient for selected materials in average humidity conditions according to PN-EN 12524 [W/(mK)] are as follows:

| No. | Material: | Heat conduction coefficient in average humidity conditions according to PN-EN 12524 [W/(mK)] [W/(mK)] |

| 1 | Aluminum alloys | 200 |

| 2 | Stainless steel | 17 |

| 3 | EPDM | 0,25 |

| 4 | PVC | 0,17 |

| 5 | Flexible PVC with 40% softening agent | 0,14 |

| 6 | Polyurethane foam (PU) | 0,05 |

| 7 | Air | 0,025 |

Soft PVC Gaskets

Gaskets made through the extrusion process from soft PVC at AiFO Components are widely used, thanks to properties that meet the stringent standards of the refrigeration industry.

Properties of PVC Gaskets:

- Multi-chamber profile – provides better thermal insulation and increases the tightness of adherence to the body.

- Shock absorber – ensures contact during the closing of doors or drawers with the body and a tight fit to the body profile.

- Quality of weld – a properly executed welded connection should be smooth and ensure the tightness of the seal at the corner.

- Magnet – a built-in magnet attracts the seal to the magnetic element installed in the profile of the refrigeration furniture body. The magnet is located in a special pocket, which is an integral part of the gasket. This solution translates into high matching and quality. The customer can choose the magnet’s polarization and the strength of attraction.

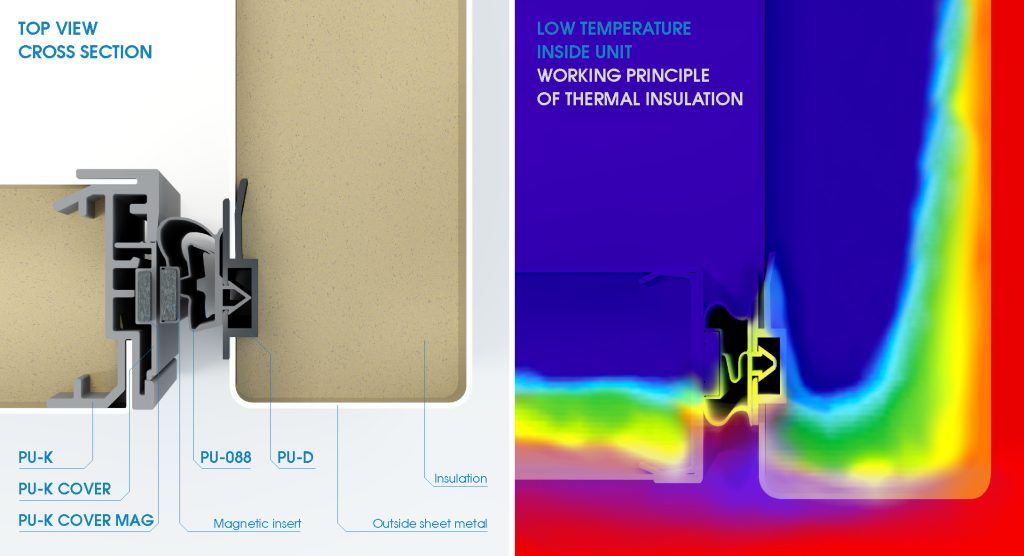

The graphic above presents a cross-section of refrigeration doors in the device and the principle of thermal insulation operation in the case of profiles and gaskets made of PVC. The drawing easily shows that energy losses are minimized, thanks to the properties of the gasket and its matching to the profile and tight adherence to the device body.

Proper Storage

At AiFO Components, we care at every stage of the process, from production to transport, to prevent gaskets from deforming. It is important to us that the product arrives in one piece to the customer in an undamaged state.

Appropriate storage of gaskets will protect them from deformation and dimensional changes, simultaneously ensuring excellent usability properties. Gaskets should be stored in dry and properly ventilated rooms, avoiding situations where the packaging may be deformed due to excessive humidity or improper storage.

The ideal storage temperature for gaskets ranges from 5 to 35°C. The air humidity should be at around 60%. Lower temperatures can lead to increased stiffness of the seal, while higher temperatures can cause dimensional changes. The proper temperature of the gasket before installation should be from 20 to 25°C. Gaskets must be kept in the original packaging in which they were delivered. It’s permissible to store outside the original packaging on specially designed stands, where the top and bottom parts of the gasket will be supported.

With proper handling, it’s easy to see that the list of advantages is long, and the gaskets offer a range of benefits. The basic benefit is the fact that PVC material is relatively inexpensive to produce. This makes it widely used in the refrigeration industry. However, this is not the only benefit of choosing gaskets made of polyvinyl chloride. Other important advantages include:

- Good chemical resistance (including acids, alkalis, oils, inorganic compounds);

- Good resistance to UV radiation;

- Good insulating properties;

- Flexibility;

- Low cost.

We warmly invite you to explore the wide range of products at AiFO Components. The full offer of gaskets is available in our “Profiles for Refrigeration Furniture” catalog and in our B2B store.

We encourage you to sign up for our NEWSLETTER, so you can follow current trends and stay up-to-date with our offer.

In case of any doubts, our technical advisors will be happy to answer all your questions. Contact details via email, phone, or the contact form are available in the CONTACT page.