Are you a manufacturer of refrigeration equipment? Don’t have people ready to create and install a refrigeration system in your device? We specialize in this, producing ready-made refrigeration systems enclosed in a single casing – cooling monoblocks. We have access to qualified staff, which eliminates time, needed resources, and gains a range of possibilities, accelerating your production. For installation in the device, a trained employee is sufficient, without specialized refrigeration knowledge. Haven’t found the right solution? We will adapt to the requirements of your device – stringent environmental standards, ecological R290 refrigerant.

Production of refrigeration and freezing monoblocks

In cooling and freezing monoblocks, we use the ecological refrigerant – propane R290, which provides high energy efficiency and safety in operation. This responds to global ecological standards and increasingly stringent norms regarding GWP and ODP indicators.

Due to the growing needs of the refrigeration market, AiFO Components continuously perfects the production processes of monoblocks and designs further Plug&Play solutions. It’s worth adding that the AiFO Components monoblock production line is located in Poland.

The monoblock is an advanced Plug&Play solution that is a complete device ensuring the maintenance of the appropriate temperature in cooled spaces in chambers, tables, showcases, and other refrigeration and freezing devices. Depending on the model, low-temperature monoblocks are designed to operate at temperatures ranging from -2°C to +8°C. Freezer monoblocks, e.g., for freezer chambers, are intended for a temperature range from -25°C to -15°C.

Every production process of cooling or freezing monoblocks begins from the design phase, where engineers use CAD software to design a device intended for a specific refrigeration furniture. AiFO Components designers advise at every stage, which eliminates potential problems at an early stage of the project. The R&D department conducts a series of tests, measurements, and performance analyses. It’s important for the device to be not only functional but also energy-efficient and safe to use.

Manufacturling lines

Our technological lines, equipped with modern machines and devices, allow for the serial production of monoblocks, ensuring high quality. Each stage of production is closely monitored, ensuring execution excellence in line with the highest standards. Delivery punctuality for our direct recipients is significant.

A key element in the production of monoblocks is the selection of appropriate components

and high precision during assembly. We use the highest class components:

- Secop, Embraco, or Cubigel compressors,

- Copper tubes prepared by our CNC machines,

- Energy-efficient EBM, EC Fans & Drives motors,

- CAREL, Dixell controllers.

This translates into long service life and reliability of monoblocks. The assembly process requires particular accuracy, so each element is carefully assembled, and the finished monoblocks are subjected to rigorous control tests.

One of the main advantages of monoblocks is their easy and quick installation. Depending on the device, the installation of a monoblock can take only a few minutes. An example of a place with quick installation is refrigeration tables, where the exchange is simple and can be performed by a person trained to carry out this operation, without specialized refrigeration training.

ADVANTAGES:

- Easy and quick process of installing monoblocks in devices;

- No MOQ;

- Applied highest quality components and materials – made of stainless steel, brand compressors (Secop, Embraco, or Cubigel), energy-efficient motors (EBM or EC Fans), controllers (CAREL or Dixell);

- Ready “Plug&Play” cooling system;

- High efficiency and quiet operation (noise level 65 dB);

- Serial production and fast turnaround time – execution even up to 14 days;

- Fast delivery and large product availability – in the offer models designed for tables, showcases, chambers, and other refrigeration and freezing devices;

- R290 – ecological refrigerant;

- Polish product.

APPLICATION EXAMPLES:

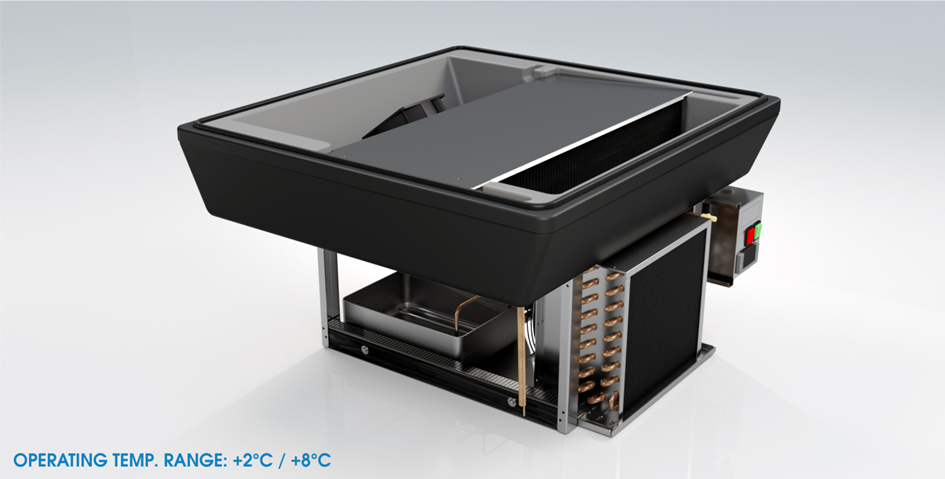

Monoblock for a cooling table

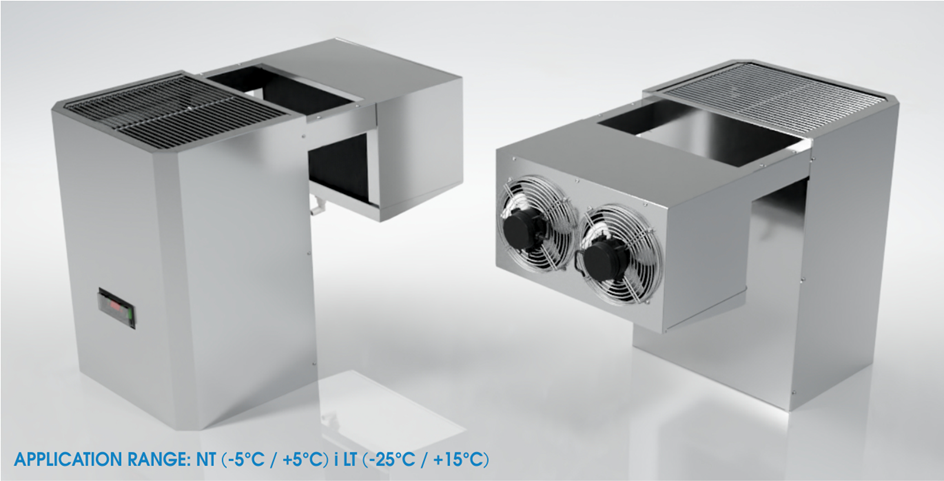

Monoblock for a cold room

Fig. Monoblock for a cold room (MB-KO)

Monoblock for a display counter

Monoblock for a vending machine

Monoblock for a cooling cabinet

We invite you to explore the extensive line of AiFO Components refrigeration monoblocks. As a manufacturer, we guarantee you individual technical care over the project and assistance

in adapting monoblocks directly to the designed devices.

We invite you to subscribe to our NEWSLETTER so that you can follow current trends and stay up to date with our offer.

In case of any doubts, our technical advisors will be happy to answer all your questions. Contact details via email, phone, or the contact form are available in the CONTACT page.