Cataphoresis

Cataphoresis is one of the methods of applying protective coatings, which uses phenomenon of electrophoresis, that is separation of chemical substance under action of electric field. Layer applied during cataphoresis to heat exchanger allows it to be protected from corrosion in comprehensive way.

What is electrophoresis?

This is electrokinetic phenomenona involving the movement of dispersed particles relative to fluid under influence of electric field. Electrophoresis of positively charged particles is called cataphoresis (movement toward the cathode), and negatively charged particles (movement toward the anode) is called anaphoresis.

Electrophoretic Deposition

Electrophoretic deposition (EPD) is widely used in many industries. It’s a broad term that includes electrophoretic coating, electrophoretic cathodic deposition and electrophoretic painting.

Electrophoretic painting, which is used to coat heat exchangers with a protective layer, involves the application of paint coatings using phenomenon of electrophoresis.

Cataphoresis painting process

Product preparation

Product is thoroughly cleaned, through the use of mechanical treatment, so that old paint coats and any signs of corrosion can be removed. Process also makes it possible to give the object right roughness. This will allow good adhesion of paint coating in the next step, which is immersion in alkaline solutions.

This step may also include application of conversion coating, which will be between the product and electrophoretic coating. Conversion coatings are often used in automotive and auto detailing.

Coating – cataphoresis painting

The object is immersed in a tank, or more precisely in a colloidal solution of paint. Direct current is then applied to the EPD liquid bath using electrodes. Typically, voltage of 25 – 400 volts is used. The object connected to current becomes an electrode, and a set of counter-electrodes completes the circuit. Colloidal particles suspended in bath, by influence of electric field, move toward the electrode and settle on it.

Rinse

The object of rinsing is to remove undeposited paint. Use of special filters allows rinsed solution to be collected and reused for cataphoresis painting process. This makes it a very efficient and at the same time environmentally friendly solution.

Paint hardening

Hardening process of coating takes place, which allows polymers to crosslink, which then makes the coating smoother and continuous.

Cataphoresis – benefits

- Controlled thickness of applied coating.

- Equal distribution of coating over entire workpiece and good coverage of workpiece, i.e. indentations, grooves, etc.

- Short coverage time.

- Ability to cover objects with continuous system.

- No negative environmental impact.

However, electrophoretic deposition method is complicated and requires specialized installation, which precludes the use of this process in small companies. It should also be remembered that in process of electrophoretic painting we cannot obtain a glossy surface, because layer is not perfectly smooth.

Cataphoresis – practical application

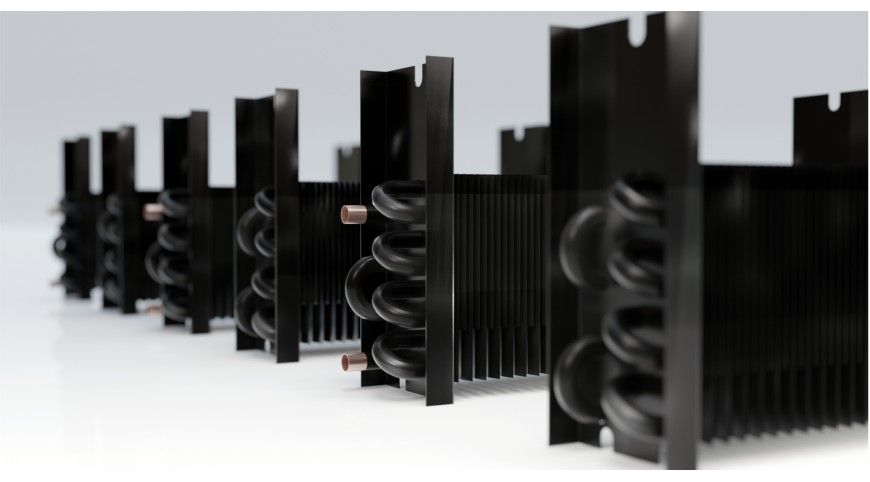

Cataphoresis is designed to protect and color any electroplated surface, so it allows it to be used in a variety of industries. It’s also used in refrigeration, where it allows protecting components such as heat exchangers. A cataphoresis-treated evaporator is more resistant to harsh conditions that often prevail inside refrigeration equipment. Protective coating, which is a set of sufficiently durable particles deposited on the device, perfectly protects heat exchanger from corrosion.

Other methods of applying protective coatings

There are many different types of protective coatings, so they are divided according to their composition, the method of applying protective layer and the type of protective mechanism. We can distinguish, for example, galvanic coatings, conversion coatings, painting coatings.

In the case of heat exchangers, another popular and common method for coating surfaces is powder coating, which also has task of protecting coated object from corrosion. Powder coating uses electrostatic phenomena to apply paint particles, and then hardening occurs. So the whole process is similar, as in cataphoresis discussed above. However, this is not the only type of protective coating. As other types of coatings are also used in heat exchangers.

Materials used for heat exchangers

Casing of exchanger is made of galvanized steel, stainless steel or aluminum. The construction and principle of operation of heat exchangers also makes materials from which such elements as pipes and fins are important. Excellent material used in the production of tubes for refrigeration industry is copper, so smooth copper tubes and internally grooved copper tubes are encountered.

Evaporator fins, on the other hand, can be made from many different materials. Fins are manufactured from:

- aluminum tape – standard solution,

- tape coated with epoxy paint,

- copper tape,

- copper sheet,

- galvanized copper,

- hydrophilic aluminum.

Wide product range

Take advantage of our wide range of heat exchangers coated with various coatings and made of different materials. We have galvanized, powder-coated and cataphoresis-treated evaporators. If you have any questions, feel free to contact our technical advisors. They will comprehensively answer any questions and help you choose the right solutions and products.