In conclusion, with the latest technology, AiFO Components has positioned itself at the forefront of the tube and pipe bending industry. The blend of expertise, modern machinery, and commitment to quality ensures that each tube, regardless of its diameter, length, or material, is bent to perfection. Whether it’s the intricate bending processes or the simple clamp and bend, AiFO Components remains a name to reckon with in the steel tube bending domain.

CNC tube bending at AiFO Components

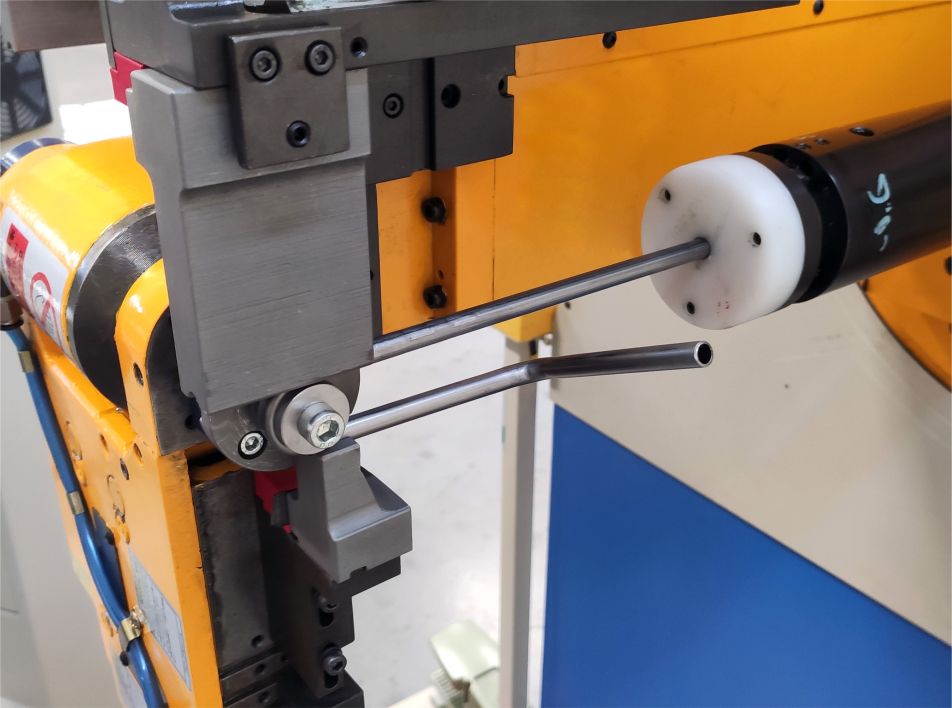

Utilizing computer numerically controlled (CNC) machinery – tube benders, AiFO Components promises repeatability and precision in steel tube bending. We offers span across 2D and 3D tube bending, endforming, and more.

Ensuring quality in every bend, all these processes are executed on state-of-the-art CNC tube bending machines. This guarantees high-quality results, optimizing the bending process and producing tubes that meet stringent specifications.

The process at AiFO Components begins with clients sending a photo of the desired part along with its dimensions. Bypassing the need for detailed technical documentation streamlines the ordering process. Experienced designers at AiFO then prepare a bending program, which is uploaded into the tube bender. This facilitates the creation of a prototype for approval. Upon green-lighting the prototype, volume production is initiated.

While CNC tube bending stands out for its precision, it’s worth noting other bending techniques such as mandrel bending, roll bending, and induction bending. Each method differs in technology and the machinery used. However, the end goal remains the same – to give a new shape to the metal pipe.

Why choose AiFO Components for bending tubes?

Opting for CNC tube bending over manual methods results in more precise outcomes and superior aesthetic qualities. Not only does this technique offer more possibilities in forming bends, especially multiple bends with different angles, but it also offers several advantages.

Main benefits:

- Time and cost savings

- Reduction of waste and tube shortages

- Capability to bend tubes of varying wall thickness and outside diameter

Furthermore, AiFO Components isn’t limited to steel. We can bend tubes made of copper, aluminium, and stainless steel, showcasing their versatility.

The comprehensive tube bending services make AiFO a preferred partner for collaboration.

Applications of steel tubes

Given its cost-effectiveness and robustness, steel tubing finds extensive use in the metalworking industry.

An essential aspect of steel tubes is their resistance to corrosion. This resistance can be enhanced using materials like stainless steel, ensuring longevity.

Interested in bending pipes? Reach out!

AiFO Components stands ready to assist. For those intrigued by bending steel tube and other materials like copper, aluminium, and stainless steel. Our experienced advisors provide essential technical support, aiding in project realization.

Moreover, we offer an extensive range of components for refrigeration and foodservice devices, including condensers, evaporators, and many other components.